Flat cold roof insulation represents an evolution in roofing technology designed to address both thermal and moisture-related challenges inherent in flat roof constructions. By maintaining the roof deck at a “cold” temperature, this approach minimises the risk of condensation, improves indoor thermal performance, and extends the longevity of the roof assembly. Its integration with traditional roofing and leadwork systems ensures not only energy efficiency but also structural integrity and regulatory compliance.

Etymology or Name Origin

The term “cold roof insulation” originates from the distinction between insulation systems where the structural deck remains unheated (cold) and those that integrate insulation with the roof deck (warm). Historically, early roofing systems were either uninsulated or used simple materials that did not significantly alter the temperature of the deck. The nomenclature evolved to differentiate systems that specifically aim to keep the roof’s substructure at ambient or lower temperatures, a concept that emerged alongside advances in both insulation materials and waterproofing techniques, including the integration of lead flashing.

Overview and Context

Flat roof insulation plays a critical role in the thermal performance and overall durability of modern roofing systems. Distinct from warm roof constructions, flat cold roof systems place the insulation below the waterproof membrane, allowing the deck to remain at a temperature that is closer to the external ambient. This configuration reduces the risk of condensation formation, a common challenge in flat roof assemblies, by creating an air gap that permits natural ventilation.

The context for this method arises from increasing energy efficiency standards and a growing demand for sustainable building solutions. As buildings are required to conform to stricter energy codes, the choice of insulation method has become pivotal. Flat cold roof insulation not only contributes to reduced energy consumption but also integrates effectively with legacy leadwork systems, providing a hybrid solution that marries modern materials with traditional construction techniques.

Principles of Roof Insulation

- Thermal Resistance: Insulation materials are engineered to slow down the transfer of heat between the interior and exterior environments. The key metric, frequently measured as the U-value, indicates the effectiveness of the material in preventing heat loss.

- Moisture Control: Effective insulation must prevent the accumulation of moisture that can lead to structural decay and reduced thermal performance. A separate vapour control layer serves to limit moisture penetration.

- Ventilation: Maintaining a ventilated gap beneath the insulation is essential to prevent condensation, ensuring that any trapped moisture is expelled efficiently.

Cold Roof Versus Warm Roof Approaches

- Cold Roof System: The insulation is installed below the waterproof membrane, creating a ventilated space that keeps the structural deck cool. This method is particularly effective in managing condensation and minimising thermal bridging.

- Warm Roof System: In contrast, the insulation is placed above or integrated with the structural deck, which keeps the entire roof assembly warm. While this can reduce heat loss, it may lead to higher risks of moisture accumulation if not properly ventilated.

- Integration with Leadworks: In both systems, traditional leadwork, such as flashing and gutters, plays a crucial role. However, cold roof systems typically allow for better thermal management alongside more effective moisture control.

History

The evolution of roof insulation has paralleled advancements in building technology and energy conservation standards. Historically, insulation was rudimentary, often using natural materials with minimal effectiveness, but these early methods laid the groundwork for today’s thermal protection strategies.

Origins and Early Developments

In the early phases of building construction, insulation methods were limited to natural and locally available materials, such as straw, wool, and simple boards. These methods provided basic thermal benefits but lacked the precision required for modern energy demands. The emergence of lead flashing as a waterproofing technique also influenced early roofing strategies, as craftsmen sought to combine insulation with effective moisture control.

Industrial Emergence

The industrial revolution brought technological improvements in material manufacturing and production techniques. The introduction of mineral wool, later followed by synthetic insulants such as expanded and extruded polystyrene, marked a significant shift in the approach to thermal insulation. These materials allowed for greater control over thermal resistance and moisture management, leading to the development of systems specifically designed to maintain a cold roof deck. Enhanced manufacturing processes and improved installation techniques enabled the systematic incorporation of these components into flat roof assemblies.

Contemporary Evolution

Modern flat cold roof insulation has emerged as a sophisticated solution that addresses both energy efficiency and moisture control. With the advent of advanced materials such as polyisocyanurate (PIR) boards, EPS/XPS panels, and multifoil boards, today’s systems offer outstanding thermal performance. Contemporary installations are subject to strict regulatory compliance, with standards like Part L of the UK Building Regulations and British Standards (BS5534, BS6229) dictating performance benchmarks. The integration of digital tools for quality control, along with improvements in adhesive technologies and mechanical fixings, has further refined the installation process, ensuring a high level of consistency and durability.

Concept and Description

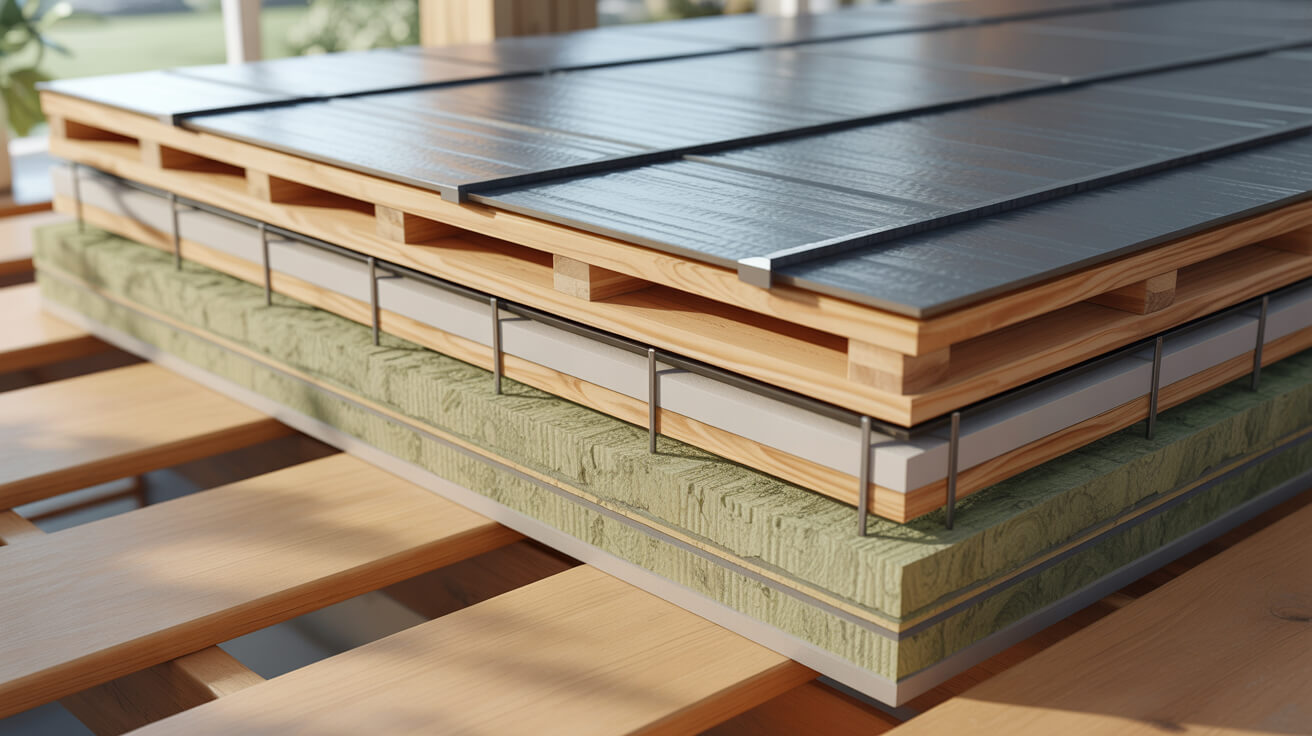

Flat cold roof insulation is defined as an insulating method where the thermal barrier is positioned beneath the waterproof membrane, leaving the structural deck unheated. This system is characterised by its distinct layered construction, which typically includes a structural deck, insulation material, vapour control layer, and an air gap that facilitates ventilation.

Definition and Key Features

- Layered Structure: The system consists of a supporting roof deck, a layer of insulating material (e.g., PIR boards or mineral wool), a dedicated vapour control layer, and a ventilated air gap beneath the waterproof membrane.

- Thermal Performance: The primary objective is to reduce heat loss by achieving low U-values. The separation of the insulation from the deck minimises thermal bridging.

- Moisture Management: A robust vapour control layer, typically constructed from polyethylene or similar materials, is critical in preventing moisture from penetrating the insulation and causing condensation.

- Integration with Leadworks: While not a direct component of the insulation system, lead flashing remains integral to the overall roofing assembly. It ensures a weatherproof seal at junctions and can be seamlessly integrated with the insulation layers.

Components and Their Roles

| Component | Description |

|---|---|

| **Structural Deck** | The base layer, typically constructed from timber, concrete, or metal, that supports all other layers. |

| **Insulating Material** | Materials such as PIR boards, mineral wool, EPS, or XPS are used for their high thermal resistance. |

| **Vapour Control Layer** | A barrier to prevent moisture ingress, ensuring that condensation is minimised. |

| **Ventilated Air Gap** | Provides necessary airflow to expel any trapped moisture, preserving the integrity of the insulation. |

| **Waterproof Membrane** | Seals the roof from water ingress, working in conjunction with lead flashing to maintain overall roofing performance. |

Comparative Analysis with Alternative Methods

The distinction between cold and warm roof systems lies primarily in the placement of the insulation. In warm roof systems, insulation is applied above or integrated with the structural deck, resulting in a warmer surface that may be more prone to condensation under poor ventilation. Cold roof systems, by contrast, intentionally keep the deck cool, thereby reducing the likelihood of moisture problems. The independent placement of insulation and the use of a dedicated vapour control layer in cold roof constructions contribute to both improved energy efficiency and enhanced durability.

Functionality, Purpose, and Applications

The primary function of flat cold roof insulation is to provide an effective thermal barrier that minimises heat loss and prevents condensation. This method is widely used to meet modern energy efficiency standards and ensure the longevity of roof assemblies across various types of buildings.

Energy Efficiency and Thermal Performance

Flat cold roof insulation significantly reduces the rate of heat transfer between the interior of the building and the external environment. The efficacy of the system is measured through the U-value, which indicates the amount of heat loss across the roof assembly. Lower U-values are directly correlated with better insulation performance. This system is particularly advantageous in colder regions where maintaining a stable internal temperature is critical for energy conservation.

Moisture Management and Condensation Prevention

A properly installed flat cold roof system addresses one of the most critical issues in flat roof construction: condensation control. The implementation of a dedicated vapour control layer ensures that water vapour from the interior does not penetrate into the insulation material, where it could condense on the cold deck and lead to problems such as mould growth and structural decay. The ventilated air gap plays a crucial role in ensuring that any accumulated moisture is effectively expelled.

Applications in Different Building Types

- Residential Buildings: In homes, flat cold roof insulation offers significant energy savings, reduced heating costs, and improved indoor comfort.

- Commercial Properties: Office buildings and retail spaces benefit from the system’s ability to maintain stable internal temperatures, thus reducing reliance on artificial heating.

- Heritage Structures: In structures where historical materials such as lead flashing are integral, a cold roof system provides a means to upgrade thermal performance while preserving traditional architectural elements.

- Retrofit Projects: Flat cold roof insulation is increasingly used in retrofit scenarios, where existing roofs require enhancement to meet modern energy standards without major structural overhauls.

Classifications, Types, and Variants

Flat cold roof insulation can be classified according to the type of insulating material used and the configuration of the overall system. These classifications help in determining the most suitable approach for specific applications.

Material-Based Categories

- PIR Boards: Known for their high thermal resistance and lightweight nature, polyisocyanurate boards provide excellent performance in cold roof systems.

- Mineral Wool: Valued for its fire resistance and acoustic properties, mineral wool is a common choice despite its relatively higher moisture sensitivity.

- EPS and XPS Panels: Expanded and extruded polystyrene panels offer a cost-effective solution with good compressive strength; however, considerations about long-term durability and moisture absorption must be addressed.

- Multifoil Boards: These systems combine rigid insulation with reflective foil layers to enhance thermal performance through radiant barrier effects.

- Natural Insulation Options: Environmentally friendly alternatives, such as sheep’s wool and recycled cellulose, provide a sustainable solution with varying degrees of insulation efficiency.

System Configurations

System configurations differ based on the specific requirements of the building, including the presence or absence of additional vapour control layers, ventilation strategies, and integration with other roof components. Some configurations may incorporate multiple insulation layers or additional sealing measures to counter local climatic variations and regulatory specifications.

Systems, Tools, and Methodologies

The installation of flat cold roof insulation involves a sequence of carefully controlled steps and the utilisation of specialised tools to ensure that the system performs as intended over its full lifecycle.

Installation Techniques

Installation methods for flat cold roof insulation are broadly categorised into adhesive and mechanical fixing. In many cases, both methods are combined to achieve an optimal bond between the insulation and the structural deck.

- Adhesive Fixing: Specialised adhesives designed for low-temperature applications are used to secure the insulation continuously across the surface. This method minimises gaps and ensures uniform contact.

- Mechanical Fixing: It involves the use of clips, fasteners, or screws to provide additional stability. This technique is particularly beneficial in areas where additional physical support is required.

- Combination Methods: In practice, a combination of both adhesive and mechanical fixings is often employed to achieve a secure and durable installation.

Quality Control and Testing

Ensuring the performance of a flat cold roof insulation system relies on stringent quality control measures:

- Pre-Installation Inspections: The structural deck and existing roof components are evaluated for integrity and preparation.

- Material Testing: Insulation materials are tested for thermal resistance, moisture absorption, and durability before installation.

- On-Site Testing: Post-installation, U-value assessments and airtightness tests are conducted to verify that the system meets performance specifications.

- Regular Monitoring: Routine maintenance and periodic inspections help identify and address potential issues early in the system’s lifespan.

Stakeholders and Entities Involved

A diverse range of stakeholders is involved in the development, installation, and maintenance of flat cold roof insulation systems. The collaboration between these entities is crucial to ensuring high-quality, compliant roof assemblies.

Key Stakeholders

- Contractors and Installers: Skilled professionals responsible for the meticulous application of insulation materials and ensuring that all layers are installed according to industry standards.

- Design and Engineering Consultants: Experts who assess building-specific requirements and advise on optimal insulation configurations based on thermal performance and architectural constraints.

- Material Manufacturers and Suppliers: Companies that provide the raw materials for insulation, vapour control layers, and related installation components. Their innovations drive improvements in insulation efficiency.

- Regulatory Bodies: Local and national authorities enforce building regulations and standards, ensuring that insulation systems comply with safety, energy efficiency, and environmental requirements.

- Property Owners and Facility Managers: The end users who benefit from the improved energy efficiency, enhanced indoor comfort, and reduced operational costs provided by advanced insulation solutions.

Legal, Regulatory, and Ethical Considerations

Flat cold roof insulation must meet a range of legal and regulatory requirements that govern the construction and renovation of buildings. These guidelines ensure that the installed systems are both safe and effective.

Compliance with Building Regulations

Insulation systems must adhere to standards set out in building regulations such as Part L of the UK Building Regulations, which focuses on energy efficiency, and specific British Standards like BS5534 and BS6229 that outline technical requirements for roofing insulation. Adherence to these guidelines guarantees that the installed systems achieve the intended energy performance and durability.

Health, Safety, and Environmental Standards

- Safety Protocols: Installation needs to conform to safety regulations, particularly those concerning working at height and the use of personal protective equipment.

- Environmental Impact: Ethical construction practices require that insulation materials are sourced and disposed of in environmentally responsible ways. This includes considerations for recycling, energy consumption during manufacturing, and the overall ecological footprint.

- Ethical Transparency: Manufacturers and installers are expected to provide clear information regarding performance metrics, such as U-values and durability predictions, ensuring that all claims are substantiated by empirical data.

Performance Metrics, Data, and Measurements

Assessing the success of a flat cold roof insulation system involves a systematic evaluation of various performance parameters.

Thermal Performance and U-Value Optimization

The U-value serves as a critical measure of insulation effectiveness. Lower U-values indicate better thermal resistance, meaning that less heat is lost through the roof assembly. Monitoring changes in the U-value before and after the installation provides tangible evidence of improved energy efficiency.

Moisture and Condensation Control

Effective insulation must prevent water vapour from condensing on the cold deck. Metrics include measuring moisture content within the roof cavity and determining the efficiency of the vapour control layer in maintaining dry conditions. These assessments help to validate the system’s ability to protect the underlying structure from moisture-related damage.

Durability and Service Life

Performance data also consider the longevity of the insulation materials and the overall system. Parameters such as material degradation, frequency of maintenance interventions, and warranty periods are analysed to assess the long-term viability of the installation.

Comparative Studies

Empirical comparisons of different insulating materials (e.g., PIR boards versus mineral wool) yield insights into the relative performance, cost-effectiveness, and ease of installation. Such data-driven analyses are essential for refining installation practices and material selection.

Challenges, Barriers, and Limitations

Despite the many advantages of flat cold roof insulation, several challenges and limitations must be acknowledged.

Technical and Installation Challenges

- Complexity of Installation: Achieving a continuous and uniform insulation layer requires high levels of skill and precision, particularly when retrofitting existing structures where the substrate may be uneven.

- Material Compatibility: Variations in material properties can lead to issues such as differential thermal expansion or moisture absorption, which can compromise the integrity of the insulation.

- Ventilation Design: Ensuring adequate ventilation to prevent condensation while maintaining airtight conditions can be technically demanding, requiring careful planning and testing.

Economic and Operational Barriers

- Initial Cost Outlay: The upfront expense associated with high-performance insulative materials and specialised installation can be significant, influencing decision-making, particularly in retrofit projects.

- Maintenance Considerations: Long-term maintenance requirements, including periodic inspections and potential repairs of the vapour control layer, represent ongoing operational costs.

- Return on Investment: Economic evaluations must consider both energy savings and associated maintenance expenses to determine the overall cost-effectiveness of the system.

Regulatory and Environmental Constraints

- Evolving Standards: As building codes and environmental guidelines continue to evolve, insulation systems must adapt to ensure ongoing compliance. Changes in regulations can require updates to installation practices or material specifications.

- Sustainability Issues: The environmental impact of synthetic insulation materials is increasingly scrutinised, prompting a need for sustainable alternatives that do not compromise on performance.

- Climate-Specific Limitations: The effectiveness of flat cold roof insulation can vary significantly based on local climate conditions, necessitating tailored approaches for regions with high humidity or extreme weather events.

Impact, Influence, and Legacy

Flat cold roof insulation has left a notable mark on the roofing industry, influencing both practical construction methodologies and regulatory frameworks.

Contributions to Energy Efficiency

By substantially reducing heat loss, these insulation systems enhance overall energy efficiency and contribute to the reduction of operational energy costs. Improved U-values, as documented in multiple performance studies, underscore the significant role of cold roof insulation in sustainable building design.

Influence on Roofing Practices and Standards

The adoption of flat cold roof insulation has influenced contemporary roofing practices, prompting the development of new standards and building codes. Its integration with traditional leadwork systems has also set a benchmark for the sustainable upgrading of historical structures without compromising their architectural integrity.

Long-Term Industry Legacy

The legacy of flat cold roof insulation is evident in the ongoing emphasis on energy conservation and thermal performance within the construction industry. As more buildings, both new and retrofitted, adopt this method, its cumulative impact on reducing carbon emissions and promoting sustainable construction practices continues to grow.

Future Directions, Cultural Relevance, and Design Discourse

Technological innovation and evolving regulatory frameworks are poised to shape the future trajectory of flat cold roof insulation, influencing both design principles and broader cultural trends in sustainable construction.

Technological Innovations and Material Advancements

Research is underway to develop advanced insulative materials that offer even lower U-values and greater durability. Nanotechnology, improved polymer formulations, and smart insulation systems that can adapt to environmental changes are areas of active investigation. These developments promise to further enhance the performance of flat cold roof insulation in various climatic conditions.

Emerging Trends in Insulation and Leadworks Integration

There is a growing trend toward a holistic approach that integrates insulation with other critical roofing components such as lead flashing, cladding, and waterproofing systems. This integration aims to create a seamless, high-performance roofing assembly that maximises energy efficiency while preserving the structural and aesthetic integrity of the building. The interplay between modern insulation technologies and traditional leadwork continues to stimulate innovation within the industry.

Predicted Shifts in Regulatory and Design Practices

As energy efficiency and sustainability become central tenets of building design, future regulations are expected to impose stricter performance criteria on roof insulation. Revised building codes may require higher thermal performance, enhanced moisture control measures, and more rigorous quality assurance protocols. Design discourses are evolving towards integration, with architects and engineers balancing aesthetic considerations, historical preservation, and technical performance in their projects.

Industry Debates and Conceptual Discourse

Current academic and professional discussions focus on reconciling the short-term economic costs with long-term sustainability benefits of advanced insulation systems. Debates continue regarding the environmental impact of synthetic insulants compared to natural or recycled alternatives, and comparative analyses are emerging to guide material selection based on lifecycle assessments. These discussions are influencing industry practices and encouraging the adoption of more resilient, eco-friendly insulation solutions.

Cultural Relevance and Design Integration

Beyond technical performance, flat cold roof insulation is becoming a symbol of sustainable modernity. As public awareness of environmental issues increases, the design and implementation of insulation systems are increasingly judged not only on performance but also on their contribution to a building’s aesthetic and cultural narrative. In heritage conservation projects, for example, modern cold roof systems are integrated carefully with traditional lead flashing to preserve historical authenticity while meeting contemporary energy standards.

Prospects for Future Research and Development

Emerging digital tools, such as Building Information Modelling (BIM) and real-time performance monitoring, are set to transform the field by enabling more precise control over installation processes and predicting maintenance needs accurately. The integration of sensor technologies and data analytics facilitates continuous performance tracking, which may in turn lead to adaptive systems that automatically adjust to varying environmental conditions. As collaborative efforts between academic research and industry practice intensify, standardised benchmarks will further refine the performance and installation of flat cold roof insulation systems.