Flat warm roof insulation has become an integral component in modern roofing systems. By placing the insulation above the deck, the system aims to maintain a continuous thermal envelope that reduces energy loss throughout the building. This arrangement not only improves energy efficiency but also mitigates the risk of moisture accumulation and subsequent damage. In buildings where leadwork—such as lead flashing and gutters—is used to ensure weatherproofing, the insulation layer works in tandem with these components to protect the structure against adverse weather conditions. Such integration is critical both for new constructions and for retrofit projects, where maintaining the integrity of heritage features is equally important.

The method is underpinned by rigorous testing protocols and regulatory frameworks that guide installation best practices. Contractors and installers are required to adhere to these standards, ensuring that the assembled roof meets performance targets such as low U-values and high fire resistance ratings. As a result, this roofing approach has gained widespread acceptance in residential, commercial, and heritage sectors.

Overview / Context

Flat warm roof insulation occupies a distinct niche within the broader roofing domain. It is particularly prevalent in flat roofing systems where energy conservation, thermal stability, and moisture management are paramount. Unlike cold roof systems—where insulation is located below the waterproofing layer—a warm roof positions the insulation above the structural deck. This configuration creates a “warm” assembly that offers several advantages:

- Energy Efficiency: By reducing conductive heat loss, the system helps lower energy consumption and maintain consistent indoor temperatures.

- Moisture Control: A properly installed vapour control layer works with the insulation to prevent condensation and related structural issues.

- Structural Longevity: The uniform temperature maintained by the insulation minimises thermal stress and helps preserve the integrity of roofing materials.

Within the context of roofing and leadworks, flat warm roof insulation also plays an important role in heritage conservation. When working with older buildings, the challenge arises in balancing modern performance with historical authenticity. The technique is carefully adapted to ensure that new installations do not detract from the aesthetic and material values of structures that may include traditional lead flashing and other historic elements.

Moreover, this approach aligns with increasingly stringent building regulations that mandate higher energy efficiency and improved indoor environmental quality. As such, flat warm roof insulation is not only a technical solution but also a regulatory necessity in many parts of the world.

History

Origins

The origins of insulation in flat roof systems can be traced to early construction practices where natural materials were used to provide basic thermal control. In historical contexts, builders employed rudimentary forms of insulation by leveraging locally available organic and mineral substances. These early methods, while not scientifically quantified, laid the groundwork for the evolution of more systematic approaches to thermal regulation.

Industrial Emergence

The advent of the Industrial Revolution spurred significant advancements in roofing technology. With improved production techniques, synthetic insulation materials began to replace traditional substances. Materials such as mineral wool and later polyisocyanurate (PIR) became widely adopted due to their superior thermal properties and consistency. This era marked the transition from artisanal applications to standardised, mass-produced solutions. Alongside these innovations, building regulations gradually emerged to set minimum performance standards, thereby standardising insulation practices across the industry.

Contemporary Evolution

In recent decades, the focus on renewable energy, sustainability, and energy efficiency has driven further development in flat warm roof insulation. Technological progress has resulted in the creation of materials that offer enhanced fire resistance, greater environmental sustainability, and improved ease of installation. Advancements in digital simulation and performance testing have also permitted more precise control over installation parameters, ensuring homogeneous application and durability.

Contemporary systems are now designed to integrate seamlessly with other components of flat roofs, such as lead flashing and drainage systems. Such integration is essential in both modern construction and the retrofitting of heritage buildings, where preserving historical aesthetics must be balanced with meeting current energy standards. The evolution of flat warm roof insulation reflects a convergence of research, regulatory influence, and market demand for systems that offer long-term cost savings and environmental benefits.

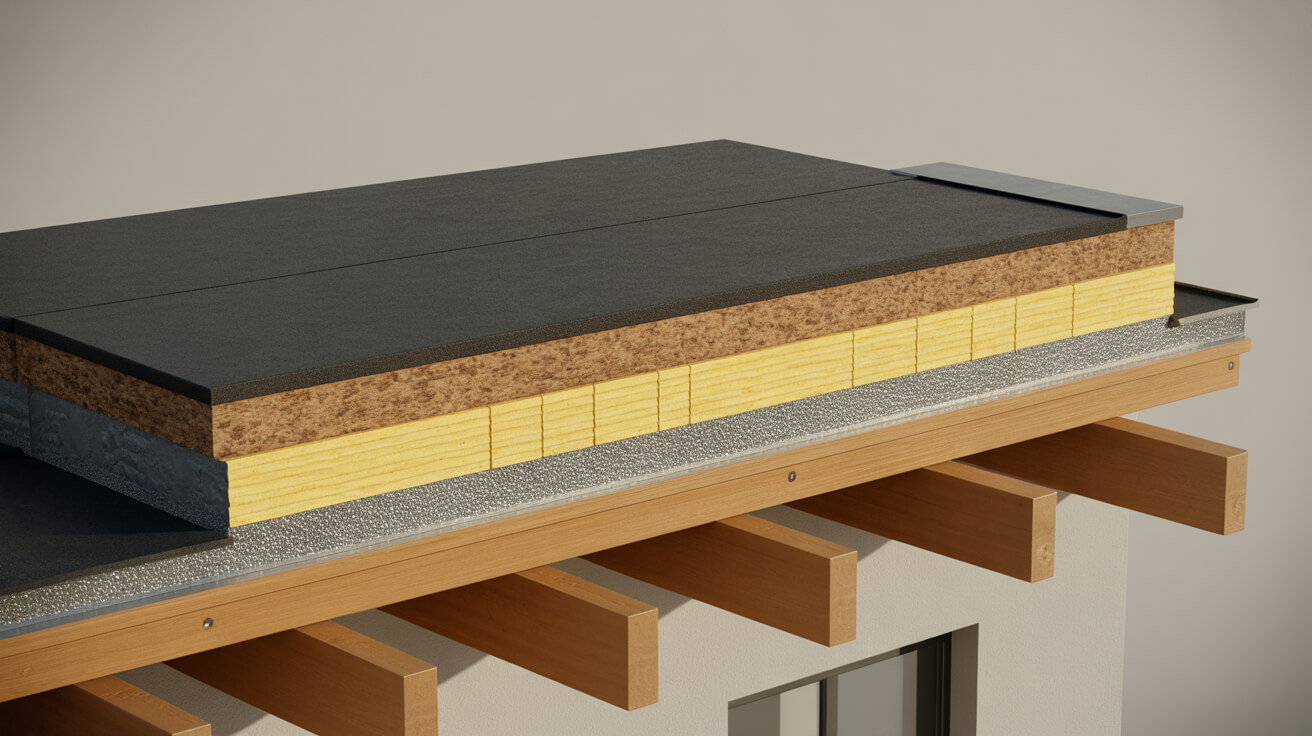

Concept / Description

Flat warm roof insulation refers to a roofing assembly in which a layer of thermal insulation is positioned above the structural deck but beneath the waterproof membrane. This configuration contrasts with colder assemblies, where insulation is often placed below the waterproofing layer. The design principle behind a warm roof is to create thermal continuity across the entire roof surface, thereby reducing heat loss and minimising the formation of condensation within the roof structure.

Key components of a warm roof system include:

- Insulation Boards: These boards are manufactured from various materials such as polyisocyanurate (PIR), mineral wool, polyurethane foam, and natural fibres. Each type is chosen based on its thermal resistance (R-value), fire rating, moisture absorption characteristics, and environmental profile.

- Vapour Control Layer (VCL): This layer is critical to prevent moisture migration from the interior or external environment into the insulation. By controlling vapour transport, a VCL significantly reduces the risk of condensation and subsequent material degradation.

- Supporting Layers: In addition to the insulation and VCL, there are typically underlay systems and fixings to ensure that the insulation remains uniformly applied. These components help secure the insulation boards and maintain the integrity of the overall assembly.

- Integration with Leadwork: In buildings that incorporate leadwork (such as lead flashing), the insulation system is designed to interface effectively with these elements to ensure seamless waterproofing and thermal protection.

The performance of a warm roof assembly is measured in terms of its U-value (a lower U-value indicates better insulation), fire resistance, and durability. Standards and testing procedures are in place to ensure the reliability and effectiveness of these systems in real-world applications.

Functionality / Purpose / Applications

The primary function of flat warm roof insulation is to provide superior thermal regulation, thereby reducing energy consumption and enhancing indoor comfort. This is achieved by establishing a continuous layer that minimises thermal bridging—a phenomenon where heat escapes through gaps or poorly insulated areas.

Key Functions:

- Thermal Efficiency: By reducing conductive heat losses from the building, warm roof insulation helps maintain stable indoor temperatures. This is especially beneficial in regions with pronounced seasonal temperature variations.

- Condensation Control: The incorporation of a vapour control layer prevents moisture build-up within the roof assembly. Effective moisture control is essential to avoid issues such as mould growth, material degradation, and structural weaknesses.

- Energy Conservation: Improved insulation performance directly correlates with reduced energy bills, as less energy is required to achieve desired internal temperatures. This is a significant advantage for property owners seeking sustainable solutions.

- Enhanced Durability: The continuity of a warm roof system contributes to the longevity of the roof structure by mitigating the stresses caused by repeated thermal expansion and contraction.

Applications:

Flat warm roof insulation is utilised across a wide range of building types:

- Residential Buildings: Homeowners use this system to improve energy efficiency, reduce heating costs, and maintain comfortable living conditions. In retrofit projects, warm roof insulation is often installed to upgrade existing roofs.

- Commercial and Industrial Properties: Businesses benefit from improved thermal performance and lower operating costs. The method also addresses compliance with stricter building codes and regulatory requirements pertaining to energy efficiency.

- Heritage and Listed Buildings: Special considerations are made for retrofitting historic buildings, where preserving the architectural integrity is as important as achieving modern energy standards. In these cases, insulation systems are carefully integrated with existing leadwork and traditional roofing materials, ensuring that both performance and historical aesthetics are maintained.

The method is chosen for its ability to deliver measurable energy savings, aesthetic integration, and enhanced structural performance. Its versatility in application makes it a preferred solution for new builds and refurbishments alike.

Classifications / Types / Variants

Flat warm roof insulation systems can be classified based on the type of insulation materials used and the specific installation techniques applied. The choice of system depends on factors such as building requirements, environmental conditions, and regulatory constraints.

Material-Based Classifications

- Polyisocyanurate (PIR) Insulation:

PIR boards are widely recognised for their high thermal resistance and low moisture absorption. Their rigid structure and high fire performance make them suitable for modern installations.

- Mineral Wool Insulation:

Known for its superior fire resistance and acoustic properties, mineral wool is favoured in applications where ecological benefits are prioritised. Its performance, however, may vary based on density and installation quality.

- Polyurethane Foam:

Offering a high insulation value and flexibility, polyurethane foam is used where precise thermal control is required. It demands careful installation to avoid potential chemical emissions.

- Natural Fibre Insulation:

Eco-friendly alternatives such as sheep’s wool or hemp provide a sustainable option. Although these materials are renewable, their performance characteristics can be less consistent compared to synthetic alternatives.

Installation Technique Variants

- Adhesive Bonding:

This method employs high-performance adhesives to attach insulation boards directly to the roof deck. It ensures a continuous bond that minimises gaps and thermal bridging.

- Mechanical Fixing:

Utilising fasteners and clips, mechanical fixing secures the insulation in place and is often employed in retrofit scenarios where adhesive bonding may be insufficient or inapplicable.

- Hybrid Systems:

A combination of adhesive bonding and mechanical fixing is used in certain conditions to provide extra stability, especially in areas with high wind loads or irregular roof surfaces.

A comparative overview is provided in the table below:

| **Material Type** | **Thermal Resistance** | **Moisture Resistance** | **Fire Resistance** | **Environmental Impact** |

|---|---|---|---|---|

| PIR | High (low U-value) | Moderate | Moderate to High | Moderate |

| Mineral Wool | Moderate | High | High | High (eco-friendly options) |

| Polyurethane Foam | High | Low to Moderate | Moderate | Variable |

| Natural Fibre | Moderate | Moderate | Low to Moderate | High (sustainable) |

Systems / Tools / Methodologies

Installation and maintenance of flat warm roof insulation require precision tools and well-defined methodologies that adhere to industry standards. The effective execution of these systems is predicated on standardised processes and specialised instruments.

Installation Methodologies

Adhesive Bonding:

- Surface preparation is meticulously performed to ensure the roof deck is clean and dry.

- A high-quality, weather-resistant adhesive is applied evenly across the substrate.

- Insulation boards are placed with care to ensure full contact without voids, reducing potential thermal bridging.

Mechanical Fixing:

- Utilises specialised fasteners and clips designed for insulation materials.

- Fixings are distributed according to manufacturer guidelines to secure the insulation uniformly.

- This method is particularly useful in retrofit applications where the roof deck may not be perfectly level.

Hybrid Systems:

- Combines both adhesive and mechanical strategies to achieve enhanced bond strength.

- Applied in complex roof geometries and areas with higher exposure to environmental stresses.

Tools and Measurement Techniques

Thermal Imaging Equipment:

- Used for post-installation checks to identify any gaps or inconsistencies in the insulation layer.

- Infrared cameras help in detecting thermal bridges, ensuring complete coverage.

U-Value Measurement Devices:

- Instruments are employed to quantify the roof’s thermal performance, verifying that the insulation meets the desired energy efficiency standards.

Moisture Metres:

- Measure moisture content within the insulation and at the interface with the waterproofing membrane, ensuring that condensation is effectively controlled.

Installation Aids:

- Tools such as guide rails, precise cutting instruments, and adhesive applicators assist in achieving a uniformly installed insulation layer.

Best Practices Guidelines

- Adhering to established building codes (e.g., BS Part L, BS EN 13501-1) is essential during installation.

- Regular inspection protocols and periodic performance tests are recommended to maintain high standards of thermal efficiency and structural integrity.

Stakeholders / Entities Involved

The ecosystem surrounding flat warm roof insulation includes various stakeholders that contribute to its effective implementation and regulation. These entities ensure that the technology remains robust, compliant, and responsive to both market demands and regulatory requirements.

Key Stakeholders

Homeowners and Property Managers:

These groups are primarily concerned with energy savings, comfort, and long-term maintenance costs. They benefit from reduced heating bills and improved structural performance.

Contractors and Roofing Specialists:

Professionals skilled in installing and calibrating insulation systems play a critical role. Their expertise ensures that the installation is carried out in accordance with industry best practices and compliance standards.

Regulatory Bodies and Certification Agencies:

Organisations that set and enforce building regulations, such as the Competent Roofer Scheme and CSCS, provide benchmarks for quality and safety. Their guidelines ensure that installations adhere to required performance and safety standards.

Manufacturers and Material Suppliers:

Companies that develop and supply insulation materials, adhesives, and specialised tools influence the technological evolution of these systems. Their research and subsequent innovation drive improvements in both performance and ease of installation.

Architects and Designers:

These professionals integrate insulation solutions within broader building designs. In projects involving heritage structures, they must balance modern energy efficiency with the preservation of historical aesthetics and leadwork features.

Legal / Regulatory / Ethical Considerations

The implementation of flat warm roof insulation is governed by a complex network of legal, regulatory, and ethical requirements aimed at ensuring safety, environmental sustainability, and long-term performance.

Regulatory Framework

Building Regulations:

In the United Kingdom, building regulations such as BS Part L detail requirements for energy efficiency in buildings. Insulation systems in flat roofs are expected to meet specific U-value targets (commonly ≤ 0.18 W/m²K), thereby ensuring minimal heat loss.

British Standards:

Standards like BS EN 13501-1 provide performance benchmarks for fire resistance, playing an integral role in assessing the suitability of insulation materials.

Industry Certifications:

Adherence to certifications such as those provided by the Competent Roofer Scheme and CSCS is essential. These certifications validate that the quality of installation and materials meets nationally recognised standards.

Ethical and Environmental Considerations

Sustainability:

Ethical construction practices emphasise the use of insulation materials that offer a lower environmental impact through life cycle assessments. This includes evaluating the sustainability of raw materials, manufacturing processes, and end-of-life disposal.

Health and Safety:

Stringent adherence to health and safety guidelines is paramount during the installation process. This involves ensuring that insulation materials do not emit harmful substances and that installation methods do not compromise worker or occupant safety.

Transparency in Performance:

Clear communication regarding performance metrics, such as U-values and fire resistance ratings, is vital. This transparency ensures that stakeholders are fully informed about the benefits and limitations of the insulation system.

Performance Metrics / Data / Measurements

Rigorous performance measurement is integral to evaluating the effectiveness of flat warm roof insulation. These metrics provide a quantitative basis for both installation verification and ongoing maintenance assessments.

Key Metrics

U-Value:

- A fundamental metric defining the rate of heat transfer through the roof assembly. Lower U-values denote better insulating performance.

Thermal Bridging:

- Quantitative assessment of areas where insulation performance is compromised due to material discontinuities. Identification of thermal bridges is critical for ensuring uniform thermal protection.

Fire Resistance Rating:

- Standards such as those outlined in BS EN 13501-1 dictate the fire performance of the insulation. High-quality systems undergo rigorous fire testing to meet established benchmarks.

Moisture Control:

- Metrics based on moisture content and vapour transmission properties ensure that the vapour control layer functions effectively. Instruments such as moisture metres provide essential data for this purpose.

Acoustic Performance (Secondary):

- Some insulation systems also contribute to sound reduction. Although not primary, acoustic data may be gathered to highlight additional benefits.

Measurement Techniques

Thermal Imaging and Infrared Scanning:

- Employed during and after installation to visualise potential areas of reduced insulation performance.

In-situ U-Value Testing:

- Devices that enable real-time monitoring of the roof assembly’s thermal performance, ensuring that the installed system meets or exceeds design specifications.

Laboratory Testing:

- Comprehensive lab tests validate the inherent properties of insulation materials, such as density, fire resistance, and moisture absorption. These tests are benchmarked against industry standards.

Periodic Inspections:

- Scheduled evaluations post-installation help in tracking the performance over time, highlighting any degradation or issues that arise during the service life of the roof.

Challenges / Barriers / Limitations

Although flat warm roof insulation offers extensive benefits, several challenges and limitations may impede its optimal performance. These issues encompass technical, operational, economic, and regulatory dimensions.

Operational and Technical Issues

Flat warm roof insulation requires meticulous installation to ensure a continuous barrier. Common technical challenges include:

- Installation Complexity:

Achieving uniform adhesive bonding or mechanical fixing without producing gaps requires high precision and specialised equipment.

- Material Degradation:

Prolonged exposure to extreme weather conditions, moisture, and UV radiation can lead to degradation of insulation materials, diminishing thermal performance over time.

- Thermal Bridging:

Inadequate installation or mismatches between materials can lead to thermal bridges, where localised heat loss occurs, reducing overall system efficiency.

- Integration Difficulties:

Retrofitting insulating systems into existing structures—especially those containing heritage leadwork—requires sensitive adaptations to avoid compromising historical fabric.

Social and Economic Factors

The deployment of advanced insulation systems is often influenced by market and economic considerations:

- Cost Implications:

High-performance insulation materials and specialised installation techniques can involve significant upfront investment. While long-term savings are achieved through reduced energy costs, initial expenditures may present a barrier.

- Maintenance Requirements:

Despite robust performance claims, periodic inspections and maintenance are necessary to ensure sustained performance. Inadequate maintenance can exacerbate issues related to thermal bridging and moisture ingress.

- Market Accessibility:

Variability in contractor expertise and the availability of quality materials can lead to inconsistent application, affecting overall reliability and performance.

Policy and Regulatory Limitations

Evolving regulatory standards may present challenges, including:

- Regulatory Compliance:

As building codes become more stringent, existing insulation systems may require modifications to achieve compliance with new energy efficiency or fire safety standards.

- Heritage Restrictions:

For historical or listed buildings, the installation methods must be tailored so as not to interfere with conservation guidelines. This often requires compromises that can restrict optimal insulation performance.

Impact / Influence / Legacy

The adoption of flat warm roof insulation has had substantial implications on both modern construction practices and long-term building performance. Its influence can be seen in multiple domains:

Contributions to Building Performance

- Energy Conservation:

By effectively reducing heat loss, warm roof insulation contributes to lower energy consumption. This, in turn, can lead to significant cost savings over the building’s lifespan.

- Enhanced Comfort:

Maintaining a consistent internal temperature enhances occupant comfort, reducing the need for additional heating or cooling.

- Moisture Control:

The system’s ability to manage condensation effectively plays a crucial role in prolonging the roof’s service life and preventing structural damages.

Industry Wide Influence

The widespread implementation of flat warm roof insulation has prompted changes in construction methods and building codes. Its influence is evident in:

- Modern Construction Practices:

The technology has catalysed advancements in roofing systems, leading to more energy-efficient designs and standardised installation practices.

- Heritage Conservation:

In retrofit projects, especially involving heritage buildings, warm roof insulation has enabled the integration of modern energy-saving techniques while respecting historical aesthetics.

- Regulatory Evolution:

The performance data generated by insulation systems continually informs updates to building regulations, driving higher standards for energy efficiency and safety.

Legacy and Long-Term Effects

- Environmental Impact:

Reduced energy consumption translates into lower greenhouse gas emissions, supporting broader sustainability initiatives. In the long run, the cumulative effect of widespread adoption contributes to environmental conservation.

- Economic Benefits:

Lower utility bills and reduced maintenance costs enhance the economic viability of properties, providing a noteworthy return on investment.

- Technological Progress:

Continuous innovation in insulation materials and installation methods reinforces the industry’s commitment to improving performance and durability, thereby cementing the technology’s legacy in modern construction.

Future directions, cultural relevance, and design discourse

Future developments in flat warm roof insulation are poised to further refine its performance, expand its applications, and deepen its cultural significance within the construction industry.

Technological Advancements

Emerging technologies are likely to drive significant improvements in insulation systems. These include:

- Smart Insulation Systems:

Integrating sensors to monitor temperature, moisture, and overall performance in real time, allowing for proactive maintenance protocols.

- Advanced Material Sciences:

The development of novel insulation materials that combine superior thermal performance with enhanced sustainability profiles will likely drive innovation. Research into materials that not only meet but exceed current performance metrics is ongoing.

- Digital Construction Tools:

Enhanced simulation and modelling software will enable more precise design and verification of insulation systems, ensuring that installations meet the exact requirements dictated by both design and performance standards.

Regulatory and Sustainability Trends

Changing regulatory standards and a growing emphasis on sustainability are influencing industry practices. Anticipated trends include:

- Stricter Building Codes:

As governments push for increased energy efficiency and reduced carbon emissions, future building regulations will likely set more stringent benchmarks for insulation performance.

- Certification and Evaluation Schemes:

New certification systems may emerge that evaluate not only energy efficiency but also the environmental impact and overall sustainability of insulation products. These metrics will drive market preference towards greener solutions.

- Lifecycle Assessments:

The environmental impact of insulation materials over their entire lifecycle—from production to disposal—will play a critical role in product selection and regulatory approval. Manufacturers will be increasingly pressured to adopt sustainable practices.

Cultural and Design Influences

The aesthetic and functional integration of insulation systems within building design is reshaping both contemporary and historical architecture:

- Heritage Integration:

For heritage buildings, there is a growing trend towards ‘invisible’ insulation solutions that provide modern performance without compromising traditional aesthetics. This requires nuanced design approaches that respect historical accuracy.

- Contemporary Sensibilities:

Modern architecture increasingly emphasises sustainability and energy efficiency as core design values. In this context, flat warm roof insulation is adopted not only for its technical merits but also as part of a broader commitment to environmental responsibility.

- Design Discourse:

Ongoing conversations in architectural circles are exploring how insulation systems can be both functionally effective and seamlessly integrated into building exteriors. This discourse covers both the technical aspects as well as cultural narratives related to sustainability and design innovation.

Industry and Research Collaboration

The future of flat warm roof insulation will benefit from closer collaboration between academic research, industry practitioners, and regulatory bodies. Key areas of focus include:

- Collaborative Innovation Projects:

Joint ventures between universities, manufacturers, and construction firms can lead to breakthroughs in material science and installation methodologies.

- Performance Data Sharing:

Open databases and shared performance metrics may accelerate improvements across the industry by enabling a more transparent evaluation of installed systems.

- Ongoing Training and Certification:

The continued evolution of industry standards will likely necessitate updated training programmes for installers and contractors, ensuring that expertise remains current with technological advancements.

By addressing these factors, the future of flat warm roof insulation is set to be characterised by continuous improvement in both performance and sustainability. The synthesis of high-performance materials, advanced installation technologies, and rigorous regulatory oversight will further cement its role as a vital component in modern roofing systems. This evolutionary trajectory is poised to offer enhanced thermal performance, increased durability, and greater environmental benefits—all of which are fundamental to the ongoing transformation of building practices.

<Ξ_RedundancyElimination>