Insulation attachment plays a central role in modern roofing systems while also bearing significance in heritage restoration projects. In contemporary construction, reliably attaching insulation materials such as polyisocyanurate (PIR), mineral wool, or expanded polystyrene (EPS) enhances a building’s energy efficiency, minimises thermal bridging, and prevents moisture ingress. In historic buildings, specialised methods integrate insulation with traditional lead flashing to maintain both performance and heritage aesthetics. This article discusses the technical methods, evolution, and regulatory framework of insulation attachment in the context of roofing and leadworks.

Overview / Context

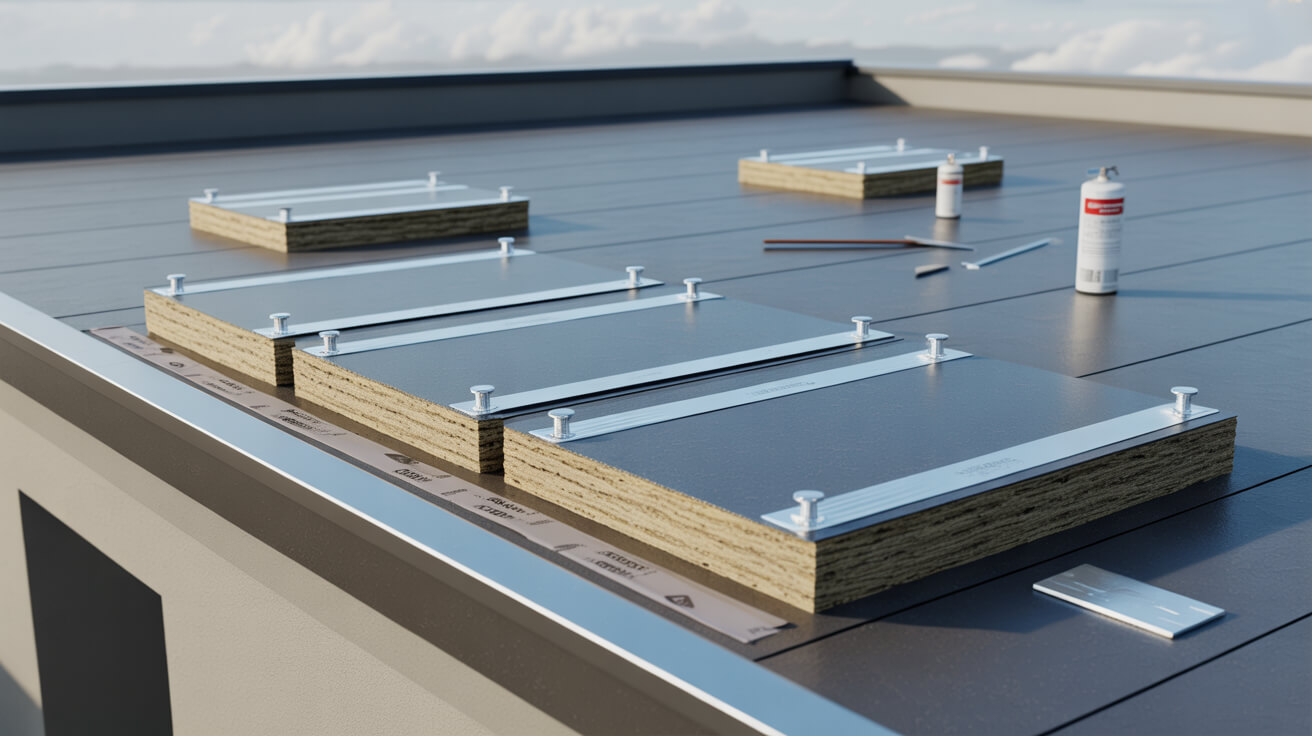

Insulation attachment is essential for achieving optimal energy conservation and structural integrity in roofing systems. It involves securely affixing insulation materials to various roof decks—be they timber, concrete, or metal—using a combination of mechanical fasteners, adhesives, and clip systems. The secure installation of insulation helps reduce heat loss, thereby lowering a building’s U-value, which is crucial for maintaining indoor comfort and lowering energy costs. Furthermore, by minimising gaps that could lead to condensation or moisture accumulation, proper insulation attachment contributes to the longevity of roofing systems.

In modern building practice, regulations such as Part L of the Building Regulations and relevant British Standards frame the methods used in insulation attachment. In parallel with these requirements, industry innovations have driven the development of diverse attachment methods that not only satisfy regulatory criteria but also address performance factors in varying environmental conditions. This focus on integration between insulation materials and traditional roof elements is particularly prominent in projects where heritage leadwork is preserved.

History

The evolution of insulation attachment reflects the broader development of roofing technology. Historically, roof insulation was not a separately defined component but rather a byproduct of the overall construction process. Early buildings, often relying on natural materials, demonstrated passive insulation properties inherent in thick masonry or thatch roofs. As construction techniques advanced, especially following industrialization, insulation materials became stand-alone products, necessitating more deliberate methods for their secure installation.

Origins

Initially, insulation was closely integrated with the roof’s primary structure. Traditional buildings used locally available materials, and the methods for securing any insulating layer were rudimentary. Simple mechanical methods such as lashing or embedding the insulation within the wall structure were common. With little understanding of thermal dynamics, early insulation techniques were largely empirical and varied by geographic region.

Industrial Emergence

The Industrial Revolution brought a surge in manufacturing capabilities and introduced synthetic insulation materials. Products such as PIR panels and rigid foam boards became widely produced, leading to standardised installation practices. During this period, attachment methods evolved to include mechanical fastening techniques with screws, nails, and later, specialised clips designed to minimise disruption of the insulation’s thermal properties. Concurrently, chemical adhesives entered the market, offering an alternative means of bonding insulation directly to roof decks. The need for consistency in installation standards gave rise to the early industry guidelines that influenced modern practices.

Contemporary Evolution

Modern insulation attachment techniques marry the precision of mechanical fastening with the continuous bonding provided by adhesive systems. Contemporary methods often employ hybrid systems in which adhesives and mechanical fixings are used in tandem, ensuring a robust and long-lasting installation. Digital tools and automated equipment now assist in tasks such as pre-drilling and adhesive application, ensuring consistency and adherence to strict regulatory standards. Furthermore, in heritage contexts, the need to integrate insulation with existing leadwork has fostered specialised techniques that respect traditional materials while achieving modern energy performance benchmarks.

Concept / Description

Insulation attachment refers to the methods and technologies used to secure insulation to a roof deck. Its primary objective is to maintain a continuous, durable bond between the insulation and the substrate, thus preserving the insulation’s effectiveness and ensuring the roof’s overall thermal integrity.

Principal Methods

The methods of insulation attachment are generally categorised as follows:

Mechanical Fastening

Mechanical fastening utilises physical devices—such as screws, nails, or specialised clips—to secure insulation materials. This approach is particularly advantageous when working with rigid insulation types. Mechanical fastening generally involves the following considerations:

- Pre-drilling: Used to accommodate fasteners without compressing the insulation.

- Fastener Spacing: Ensures even distribution of load and minimises potential thermal bridging.

- Material Compatibility: Fasteners must be chosen based on the characteristics of both the insulation and the underlying deck.

Adhesive Bonding

Adhesive bonding uses chemical agents to create a bond between the insulation and the roof deck. Common adhesives include acrylic, bituminous, and epoxy-based formulations. Adhesive bonding is often preferred for:

- Continuous Coverage: Providing a uniform bond that minimises gaps.

- Flexibility: Particularly useful for insulation materials that may deform under mechanical pressure.

- Surface Sensitivity: Ideal when the roof deck cannot tolerate mechanical penetration.

Clip Systems

Clip systems involve the use of engineered clips or brackets that secure insulation in place without directly penetrating the insulation material. This method is employed when:

- Minimising Damage: The insulation material is sensitive to compression or penetration.

- Dynamic Adaptation: Temporary holding is required before permanent adhesives cure.

- Compatibility: The installation process requires non-invasive attachment, particularly in retrofit applications.

Hybrid Systems

Hybrid systems combine the benefits of mechanical fastening and adhesive bonding. By using both methods, installers can achieve a robust bond that harnesses the long-term strength of mechanical fixings whilst benefiting from the seamless continuity of adhesives. Hybrid systems are especially effective in environments where:

- Complex Roof Decks: Multiple substrate types are present.

- Extreme Weather Conditions: Enhanced resistance to environmental stresses is needed.

Material Interfaces and Integration

A critical component of insulation attachment is the interface between the insulation and the roof deck. This interface must be engineered to accommodate differences in thermal expansion, prevent moisture accumulation, and ensure a continuous bond. In many installations, additional layers—such as a vapour control layer (VCL) or even a specialised lead flashing—are employed to bridge these differences.

In heritage roofing, where traditional leadwork is a fundamental component, the method of attachment must not only secure modern insulation but also harmonise with historic materials. The particular challenge is to meet modern performance standards without compromising the aesthetic or physical integrity of the leadwork. Techniques have been developed to integrate adhesion systems with traditional flashing, ensuring that both components function together to provide a durable, high-performance roof.

Functionality / Purpose / Applications

The primary function of insulation attachment is to maintain the integrity of the insulation layer and, by extension, the overall performance of the roofing system. Effective insulation attachment offers the following benefits:

- Enhanced Thermal Efficiency: Secure attachment reduces heat loss by minimising gaps that allow thermal bridging, thereby maintaining low U-values and reducing energy consumption.

- Moisture and Condensation Control: A continuous, well-attached insulation layer prevents moisture ingress and condensation, which can lead to material degradation and structural damage.

- Improved Durability: Proper insulation attachment increases the longevity of both the insulation and the roofing system by protecting against environmental wear and tear.

- Regulatory Compliance: Adhering to proper installation techniques ensures compliance with local and national building regulations, reducing risks associated with non-compliance.

Applications Across Building Types

Insulation attachment is relevant across a wide array of applications:

- Residential: In homes, effective insulation attachment contributes to lower heating and cooling bills, improves indoor comfort, and protects against structural damage resulting from moisture.

- Commercial: In office spaces, retail centres, and other commercial properties, reliable insulation improves energy management, which translates to operational cost savings and a more consistent environment for occupants.

- Heritage and Listed Buildings: For historically significant structures, insulation attachment methods must be adapted to preserve traditional materials, such as lead flashing, while upgrading thermal performance. This requires a delicate balance between modern performance criteria and heritage conservation.

- Industrial: In industrial settings where large roof spans and high-load conditions prevail, robust insulation attachment techniques ensure that insulation remains effective under demanding operational conditions.

Classifications / Types / Variants

Insulation attachment methods can be segmented into a taxonomy that facilitates the selection process for various roofing projects. The common classifications include:

| **Method** | **Description** | **Typical Applications** |

|---|---|---|

| Mechanical Fastening | Use of physical devices (screws, nails, clips) to grasp the insulation to the substrate. | Rigid insulation on uneven or high-load surfaces. |

| Adhesive Bonding | Application of chemical adhesives that form a continuous and uniform layer between insulation and deck. | Flexible insulation systems or delicate materials. |

| Clip Systems | Utilisation of engineered clips for non-invasive attachment without penetrating the insulation. | Retrofit scenarios and installations with sensitive materials. |

| Hybrid Systems | An integrated approach that combines both mechanical and adhesive techniques. | Complex installations requiring both strength and uniformity. |

Each variant is chosen based on factors such as the type of insulation used, substrate characteristics, environmental conditions, and regulatory requirements. Hybrid systems have emerged as a preferred option in many instances due to the complementary benefits they offer, ensuring both immediate structural integrity and long-term bond durability.

Systems / Tools / Methodologies

The implementation of insulation attachment is supported by a suite of tools and methodologies that ensure both precision and consistency. These systems are critical for achieving the desired performance in both new constructions and retrofits.

Installation Tools

- Drills and Pre-drilling Equipment: These tools are essential for creating precise pilot holes in both the roof deck and insulation material, reducing the risk of material compression.

- Fastening Devices: A range of screws, nails, specialised brackets, and clips designed to work with various insulation types are employed, ensuring the insulation remains securely attached.

- Adhesive Dispensers: Hand-held or automated dispensers that apply adhesives at consistent rates, ensuring an even bond across the interface.

- Measuring Instruments: Tools such as laser levels and digital micrometres are used to ensure that fasteners are evenly spaced and that surfaces are prepared according to recommended tolerances.

Methodologies

- Surface Preparation:

Effective insulation attachment begins with proper preparation of the roof deck. This involves cleaning, drying, and priming the substrate to remove contaminants that may impede adhesion. Pre-drilling is often necessary to prevent undue stress on insulation materials.

- Application of Adhesives:

Adhesive application demands controlled environments. Parameters such as temperature, humidity, and curing time are critical. Manufacturers provide specific guidelines that must be adhered to for optimal bond strength.

- Mechanical Fixing:

When employing mechanical fastening methods, the spacing of fasteners, pre-drilling procedures, and the determination of load distributions are integral to ensuring that the attachment does not compromise the insulation’s performance.

- Hybrid Techniques:

In hybrid systems, the process involves both adhesive application and mechanical fixing. The methodologies require synchronisation between the two processes to avoid interference. For instance, fasteners might be installed following an initial phase of adhesive curing to reinforce the bond.

Quality Assurance

- Thermal Imaging:

Post-installation, thermal imaging is used to detect any inconsistencies in the insulation installation. Gaps or areas of insufficient coverage can be identified, enabling immediate remediation.

- Moisture Detection:

Moisture sensors and infrared thermography assist in verifying that the insulating layer is not compromised by moisture, a common cause of performance degradation.

- Load Testing:

Especially in high-wind or high-load environments, load tests are performed to ensure that the insulation attachment can sustain both static and dynamic pressures without failure.

Stakeholders / Entities Involved

A diverse range of professionals and organisations plays a role in the insulation attachment process. Each stakeholder contributes to ensuring that the installation meets both performance and regulatory standards.

- Roofing Contractors and Installation Specialists:

These experts are responsible for the practical aspects of installation, from surface preparation and adherence to fastener spacing guidelines to the precise application of adhesives. Their expertise is crucial in both new builds and refurbishment projects.

- Material Suppliers and Manufacturers:

Suppliers provide the critical components required for insulation attachment, including fasteners, adhesives, and insulation materials. Their product specifications and performance data are essential for selecting the appropriate methods.

- Regulatory Authorities and Certification Bodies:

Organisations responsible for establishing and enforcing building regulations ensure that installations meet national standards, such as energy efficiency and fire safety. Regulatory compliance is vital for both modern and heritage projects.

- Heritage Conservation Experts:

In projects involving historical buildings, conservation specialists guide the adaptation of modern attachment methods to preserve traditional materials such as original lead flashing. This collaborative approach ensures that energy performance upgrades do not diminish the building’s cultural and architectural value.

Legal / Regulatory / Ethical Considerations

Insulation attachment must be executed in conformity with a range of legal and regulatory standards that safeguard both performance and safety. These include national building codes and British Standards that set benchmarks for installation quality, thermal performance, and moisture control.

- Building Regulations:

Regulations such as Part L of the Building Regulations provide guidelines on energy efficiency, mandating that insulation installations achieve specific U-values. Compliance with these regulations is critical, not only for energy performance but also for ensuring that the installation is safe and durable.

- British Standards:

Detailed specifications are provided by standards such as BS EN 1604 and BS8612, which outline the acceptable methods and performance criteria for insulation attachment. Adhering to these standards is essential for quality assurance and long-term performance.

- Health and Safety Legislation:

Installation procedures must comply with health and safety regulations, mandating the use of proper personal protective equipment (PPE) and safe working practices during installation. This includes the correct handling of adhesives and mechanical fasteners.

- Ethical Considerations:

In heritage restorations, ethical concerns arise regarding the preservation of the building’s traditional character. Contractors must balance the need for modern insulation performance with the imperative to preserve traditional leadwork and other historical materials. This often necessitates bespoke methods that harmonise modern efficiency with historical authenticity.

Performance Metrics / Data / Measurements

Evaluating the success of insulation attachment involves various quantitative and qualitative metrics. Ensuring that installations meet defined performance standards requires systematic measurement and ongoing monitoring.

- Thermal Performance Indicators:

The U-value of a roof is a primary measurement of thermal efficiency. Lower U-values indicate better insulation performance. Reducing thermal bridging through secure insulation attachment further enhances these values.

- Moisture Control Measurements:

Effective insulation should prevent condensation and moisture ingress. Infrared thermography and humidity sensors are used to detect any potential moisture issues, ensuring that the insulation remains effective over time.

- Durability and Longevity Tests:

Load testing and periodic inspections are essential for verifying that the insulation attachment remains secure under operational stresses. The results of these tests inform maintenance schedules and the anticipated lifespan of the system.

- Installation Consistency:

Uniformity in fastening or adhesive application is measured through quality control processes. Variations in spacing, over-compression, or inadequate adhesion may be identified through systematic inspections, ensuring consistency across the entire roofing surface.

Challenges / Barriers / Limitations

Several technical, economic, and regulatory challenges can affect the success of insulation attachment. Addressing these barriers is crucial for achieving optimal performance and compliance.

Operational or Technical Issues

- Substrate Variability:

Roof decks can vary significantly in material and condition (timber, concrete, metal), influencing the selection of an appropriate attachment method.

- Installation Precision:

Inadequate surface preparation, imprecise fastening, or inconsistent adhesive application can lead to poor performance. Pre-drilling and careful measurement are essential components of the process.

- Environmental Factors:

Temperature and humidity fluctuations during installation can affect adhesive curing and fastener performance, potentially compromising the bond.

Social or Economic Factors

- Cost Implications:

High-quality materials and precise installation techniques may lead to increased upfront costs, which must be balanced against long-term energy savings.

- Labour Availability and Expertise:

The success of insulation attachment depends on skilled workmanship. Variability in skills among contractors can lead to inconsistencies in quality.

- Market Pressures:

Economic constraints and competitive pressures may lead to compromises in material selection or installation practices, affecting overall performance.

Philosophical or Political Objections

- Traditional vs. Modern Methods:

In heritage projects, debates persist over the use of modern attachment methods versus traditional techniques. Stakeholders must manage expectations and reconcile differing philosophies of preservation and renovation.

- Regulatory Compliance:

Frequent updates or changes in relevant building codes and standards necessitate ongoing adaptation by contractors, potentially causing friction between established practices and new requirements.

Impact / Influence / Legacy

The successful execution of insulation attachment has a pronounced effect on the durability and performance of roofing systems. In practical terms, effective insulation attachment enhances building energy efficiency, reduces maintenance needs, and extends the lifespan of roofing structures.

- Energy Efficiency Gains:

By ensuring a continuous barrier against heat loss, proper insulation attachment results in lower energy consumption—a benefit that is both economically and environmentally significant.

- Extended Roof Longevity:

Secure attachment methods reduce the likelihood of insulation displacement, mitigating the risk of structural damage and thereby extending the service life of the roofing system.

- Industry Influence:

Advances in insulation attachment techniques and materials contribute to the evolution of building standards and best practices. Innovations in this field drive subsequent developments in construction technology, influencing broader industry trends.

- Preservation of Heritage:

In historic buildings, the careful integration of modern insulation with traditional leadwork demonstrates how contemporary techniques can enhance performance without compromising cultural integrity.

- Economic and Environmental Benefits:

In the long term, improved insulation attachment results in reduced energy costs, less frequent repairs, and a lower carbon footprint. These cumulative effects contribute significantly to sustainable building practices.

Future directions, cultural relevance, and design discourse

Emerging trends in material science and construction technology are poised to redefine insulation attachment in both new constructions and heritage restorations. Ongoing research into advanced adhesives, fasteners, and hybrid systems is expected to yield solutions that further improve the speed, reliability, and durability of insulation installations.

Technological advancements such as Building Information Modelling (BIM), augmented reality (AR) for on-site assessments, and automated fastening systems are anticipated to streamline installation processes and enhance quality control. As these tools become integrated into industry practice, stakeholders will likely benefit from more consistent application and real-time performance monitoring, enabling adaptive responses during installation.

Philosophical and cultural discussions surrounding insulation attachment are also evolving. In today’s context, sustainability is not only a performance metric but a culturally significant goal. Future discourse will likely explore the balance between innovative insulation technologies and the preservation of historic architectural features. The integration of energy-efficient solutions into heritage renovations reflects a growing commitment to both functional performance and cultural conservation.

Furthermore, regulatory bodies continue to update and refine standards as new materials and techniques emerge. This evolution drives an ongoing dialogue among industry experts, regulatory agencies, and academic researchers, fostering an environment where best practices are continually improved through collaborative insight.

The legacy of insulation attachment is measured not only by its immediate impact on energy performance and building durability but also by its influence on future construction methodologies. As the industry moves towards greater digital integration and smart building solutions, the concepts underlying insulation attachment will likely form part of a broader trend towards integrated, adaptive systems that harmonise traditional craftsmanship with modern efficiency.

Innovative materials, such as next-generation adhesives and fasteners engineered for hybrid performance, are already in development. These advancements are expected to set new industry benchmarks, with a focus on achieving optimal thermal performance while simplifying the installation process. As such, the future of insulation attachment is intertwined with the broader trajectory of sustainable construction and the drive to reduce the environmental impact of buildings.

In summary, insulation attachment represents a paradigm of modern roofing technology that merges engineering precision with nuanced material compatibility. Its evolution—from rudimentary, traditional methods to highly engineered, hybrid systems—illustrates both the progress and the complexity of contemporary construction practices. As technological innovations and regulatory standards continue to evolve, the ongoing refinement of insulation attachment methods will remain central to achieving high-performance, sustainable, and resilient roofing systems for the future.