Tapered insulation is increasingly recognised as an integral component in modern roof assemblies, particularly in systems where enhancing both water management and thermal efficiency is critical. It operates by establishing a continuous gradient that guides water towards drainage outlets, thereby reducing the risks of leaks and moisture-related structural damage. Its application is especially valuable in contexts where traditional lead flashings coexist with contemporary building materials, creating bridges between modern energy efficiency practices and established construction techniques.

The implementation of tapered insulation has evolved alongside advancements in material science and construction methodologies. Over time, it has transitioned from an experimental concept into a vital tool within the roofing industry—addressing the dual challenges of energy conservation and water management. Its integration into roof systems is guided by rigorous standards and regulatory requirements, ensuring that installations achieve the desired performance under a variety of environmental conditions.

Etymology or Name Origin

The term “tapered insulation” originates from the word “taper,” which signifies a gradual diminution in thickness. This terminology reflects the core design principle of the product—a continuously varying insulation layer that creates a built-in slope. The historical usage of the term has evolved within the architectural and engineering fields, where precision in material application and drainage design has become essential. Within the context of modern roofing, the term embodies both a functional and aesthetic approach, merging traditional concepts of roofing with innovative insulation solutions.

Overview / Context

Tapered insulation represents a notable advancement in the realm of roofing insulation, addressing the limitations of uniform insulation systems by incorporating a gradient that actively enhances water movement. This product is particularly relevant in applications where flat roofs are susceptible to water accumulation and thermal inefficiencies. By integrating a tapered profile into the insulation, the system not only provides high thermal resistance but also facilitates effective water drainage, thereby improving the overall performance and longevity of the roof assembly.

In the broader context of building science, tapered insulation is part of a comprehensive strategy aimed at minimising energy loss while ensuring structural integrity. Its design is aligned with contemporary regulatory frameworks that demand both high-performance insulation and stringent water management. The importance of such solutions has grown as architectural designs evolve to meet increasingly demanding environmental and performance standards, highlighting the ongoing refinement in both material technology and installation methodologies.

History

Origins

The conceptual basis for tapered insulation emerged in the mid-20th century as engineers sought to address the intrinsic limitations encountered with flat, uniform insulation systems. Early research into polymeric and foam materials revealed that a graded insulation profile could be engineered to direct water away from roof surfaces while providing superior thermal protection. Initial prototypes were developed through laboratory experiments that balanced material composition with structural performance, setting the stage for broader industrial application.

Industrial Emergence

During the latter half of the 20th century, the roofing industry began to adopt tapered insulation as a viable solution for water management and energy efficiency. Technological advances in polymer manufacturing enabled the production of insulation boards with precise thickness gradients. This period saw the standardisation of tapered insulation products, which were integrated into large-scale roofing projects across commercial and residential sectors. Manufacturers refined production processes to ensure consistency and reliability, transforming tapered insulation from an experimental concept into a routine element of modern roofing.

Contemporary Evolution

In recent decades, tapered insulation has undergone significant evolution, driven by advances in both material science and installation techniques. Modern systems benefit from enhanced formulations that improve thermal performance, durability, and moisture resistance. Innovations in installation methodologies—ranging from high-performance adhesives to robust mechanical fastenings—have further solidified the role of tapered insulation in integrated roofing systems. Current research focuses on optimising design parameters through sophisticated computer modelling, ensuring that installations meet or exceed prescribed regulatory standards. As a result, tapered insulation now represents a critical component in the design of energy-efficient, sustainable, and resilient roofing assemblies.

Concept / Description

Tapered insulation is defined by its variable thickness, engineered to promote a gradual slope across the roof surface. This gradient facilitates effective drainage, thereby reducing the risk of water pooling and subsequent structural deterioration. The product is specifically designed to counteract the limitations of uniform insulation layers, which can create areas vulnerable to moisture ingress and thermal bridging.

Core Principles

At the core of tapered insulation is the principle of creating a built-in slope that improves water runoff from roof surfaces. This design minimises the potential for condensation and water accumulation, which are common problems in flat or low-slope roofs. In addition to promoting drainage, the tapered profile significantly reduces thermal bridging by ensuring a more consistent barrier against heat transfer. This dual functionality is essential in maintaining optimal energy efficiency, as it reduces heat loss during colder months and helps to moderate indoor temperatures during warmer periods.

Composition and Materials

Tapered insulation products are typically manufactured using a range of materials, each selected for its unique thermal and structural properties. Common base materials include:

- Polyisocyanurate (Polyiso): Valued for its high insulating properties and superior R-value performance, making it ideal for projects that prioritise energy efficiency.

- Expanded Polystyrene (EPS) and Extruded Polystyrene (XPS): These materials are favoured for their balance between performance and cost-effectiveness. They provide adequate insulation while maintaining a degree of moisture resistance.

- Hybrid Compositions: Some systems integrate multiple materials to achieve a balance of benefits from each component, providing enhanced durability and improved moisture management.

The manufacturing process involves creating insulation boards with a controlled gradient in thickness. This is achieved through precision moulding and advanced layering techniques, ensuring that the final product consistently meets required performance standards.

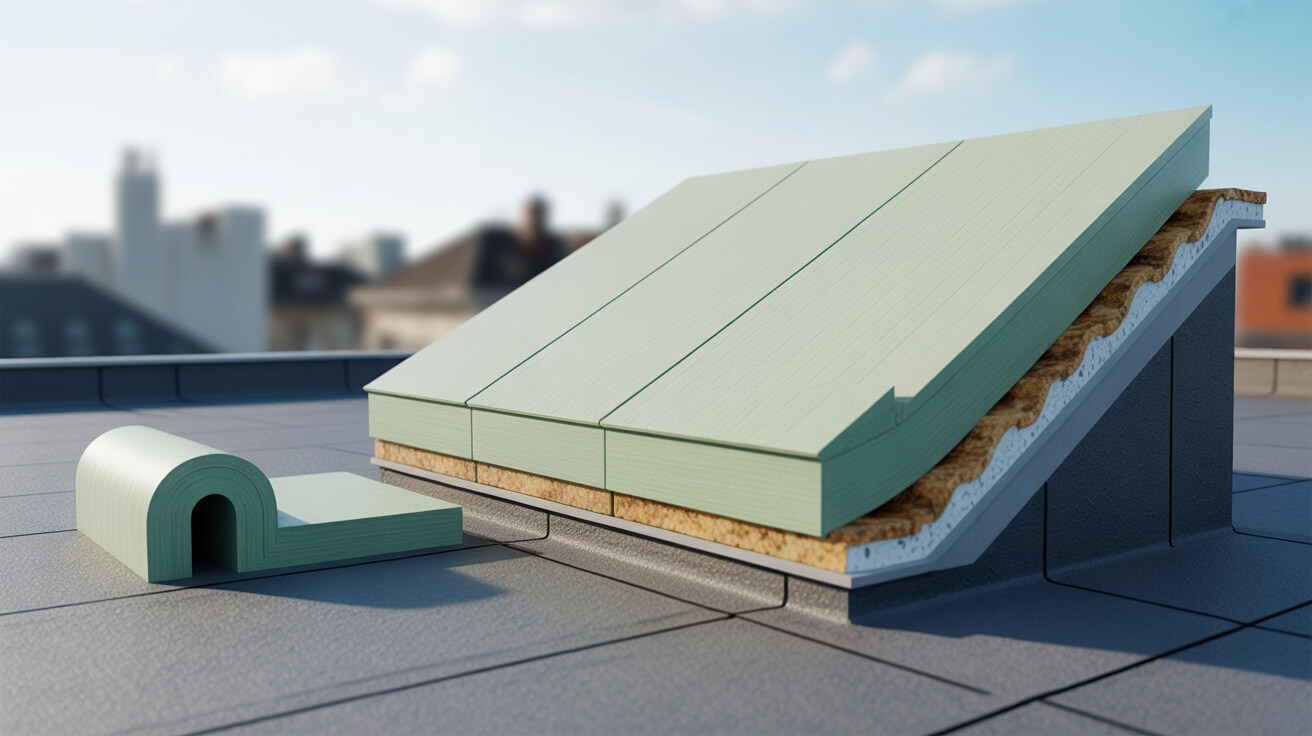

Structural Integration

In practical applications, tapered insulation is installed as a component of a multi-layer roofing system. The typical assembly begins with the roof deck, followed by the tapered insulation layer, which is then overlaid by a vapour control barrier and a waterproof membrane. The integration with lead flashing becomes particularly significant in heritage or retrofit scenarios, where traditional leadwork must be preserved while still accommodating modern insulation technology. By carefully engineering the interface between tapered insulation and lead components, installers can create roofs that are both functionally efficient and aesthetically harmonious.

Installation Techniques

The installation of tapered insulation involves methods designed to preserve the integrity of the gradient while ensuring a secure bond to the roof deck. The two primary methods include:

- Adhesive Bonding: High-performance adhesives are applied to secure the insulation, creating a continuous and seamless integration across the roof surface.

- Mechanical Fastening: In cases where additional structural support is required, mechanical fixings such as screws or clips are used. These fasteners are strategically placed to maintain the designed taper and to provide extra stability, especially in regions subject to extreme weather conditions.

Both methods are employed with strict adherence to industry standards to ensure optimal performance and longevity.

Functionality / Purpose / Applications

Tapered insulation is employed primarily to address specific deficiencies in traditional roofing insulation systems, with its design focusing on improving both moisture management and thermal performance. By incorporating a slope within the insulation layer, this product is able to effectively direct water towards drainage outlets, thereby reducing the occurrence of water pooling—a common precursor to roof leaks and structural failures.

Key Functional Benefits

- Enhanced Water Drainage: The built-in gradient ensures that water is systematically directed to appropriate drainage points, minimising moisture accumulation and reducing the risk of leaks.

- Improved Thermal Efficiency: By reducing thermal bridging and creating a continuous insulation barrier, tapered insulation helps diminish heat loss, contributing to more energy-efficient building envelopes.

- Condensation Reduction: The effective drainage provided by tapered insulation limits the formation of condensation, which can lead to mould growth and degradation of roof components.

- Compliance with Building Standards: Tapered insulation systems often meet stringent regulatory requirements, making them suitable for new construction as well as retrofit projects where building codes demand high levels of energy efficiency and moisture control.

Applications in Various Sectors

- Residential Roofing: Homeowners benefit from enhanced insulation performance that translates to lower energy bills, improved comfort, and extended roof lifespan. Tapered insulation is particularly advantageous in flat roofs or low-slope roof designs.

- Commercial Buildings: Large-scale roofing systems in commercial establishments rely on tapered insulation to maintain temperatures, reduce energy consumption, and manage water drainage effectively, meeting the rigorous demands of large, flat roof areas.

- Heritage and Conservation Projects: In projects involving historical buildings, tapered insulation is carefully integrated with traditional lead flashing and other heritage materials. This ensures that while modern insulation technology is applied, it does not compromise the character and structural integrity of historically significant structures.

Classifications / Types / Variants

Tapered insulation products are available in several variants, differentiated primarily by the material composition, method of installation, and design approach.

Material-Based Variants

- Polyiso-Based Systems: These systems are characterised by their high thermal resistance and superior R-value, making them suitable for applications where energy efficiency is a top priority.

- EPS/XPS-Based Systems: Often chosen for their cost-effectiveness, these systems offer reasonable thermal performance and are widely used in both residential and commercial applications.

- Hybrid Systems: Some manufacturers have developed hybrid systems that combine different materials to balance thermal performance with moisture resistance and structural durability.

Installation-Based Variants

- Adhesively Bonded Systems: In these systems, the tapered insulation is bonded to the roof deck using high-performance adhesives. The method is ideal for achieving a seamless, continuous surface that maintains the integrity of the gradient profile.

- Mechanically Fastened Systems: This method employs mechanical fasteners—such as screws or clips—to secure the insulation. It is particularly advantageous in applications that demand additional support due to high load requirements or challenging environmental conditions.

Design-Based Variants

- Continuous Gradient Designs: These designs feature a uniformly varying thickness across the entire span of the insulation, ensuring that water is evenly directed to drainage points.

- Segmented Gradient Designs: Certain systems use segmented or modular insulation pieces with differing thicknesses. These segments are arranged to create an overall tapered profile, an approach that can be beneficial in complex roof geometries where a continuous gradient is difficult to achieve.

Systems / Tools / Methodologies

Robust systems and methodologies are essential to ensure that tapered insulation is installed correctly and performs as expected over its operational lifespan.

Installation and Performance Methodologies

- Adhesion Testing: Prior to installation, materials are subjected to rigorous adhesion tests to verify the bond strength between the insulation and the roof deck. This ensures durability and consistent performance.

- Mechanical Fastening Protocols: Standard protocols define the proper spacing and placement of mechanical fasteners. These guidelines are critical for maintaining the integrity of the tapered design.

- Quality Assurance Procedures: Following installation, quality assurance measures are implemented. These include visual inspections as well as technical evaluations using thermal imaging and water flow analysis.

Performance Assessment Tools

- Thermal Imaging: Thermal cameras are employed to identify areas of heat loss, which may indicate gaps or inconsistencies in the insulation. This tool is integral for ensuring that the system performs as expected.

- Water Flow Analysis: Field assessments measure the water runoff efficiency of the tapered insulation, confirming that the designed gradient effectively channels water to drainage points.

- Adhesion and Fastening Evaluations: Mechanical tests assess the long-term stability of the insulation, ensuring that both adhesive bonds and mechanical fixings are robust under various environmental conditions.

Methodological Framework

- Standardised Test Methods: The performance of tapered insulation is evaluated using standardised methods and metrics, such as U-value, R-value, and lambda value measurements, which provide a clear indication of its energy efficiency.

- Regulatory Benchmarks: Installation and performance are aligned with regulatory frameworks, ensuring compliance with building regulations, notably Part L and various British Standards.

- Continuous Monitoring: Post-installation monitoring using both manual inspections and sensor technologies aids in the early detection of potential issues, ensuring that the insulation system maintains its efficacy over time.

Stakeholders / Entities Involved

The application and maintenance of tapered insulation within roofing systems involve multiple stakeholders, each contributing to the overall efficacy and reputation of the technology.

Industry Practitioners

- Roofing Contractors: These professionals are responsible for the installation of tapered insulation systems. Their expertise and adherence to quality standards are crucial to the optimal performance of the insulation.

- Architects and Engineers: They play a pivotal role in designing roof assemblies that integrate tapered insulation seamlessly. Their designs must balance structural, thermal, and aesthetic considerations.

- Building Owners and Property Managers: Stakeholders responsible for ensuring the long-term performance of their building envelopes rely on tapered insulation to support energy conservation and reduce maintenance needs.

Regulatory and Standards Bodies

- Building Control Authorities: Local and national agencies enforce building regulations that mandate energy efficiency and moisture management standards in roofing systems.

- British Standards Institutions: Organisations that develop and update standards, such as BS6229 and BS5534, provide the technical guidelines that underpin the performance of tapered insulation.

- Certification Organisations: Programmes that certify contractors and material manufacturers, ensuring that installations meet stringent quality criteria, are instrumental in maintaining high industry standards.

Manufacturers and Suppliers

- Material Manufacturers: Companies producing polyisocyanurate, EPS/XPS, and hybrid insulation systems are essential to the supply chain, providing the raw materials for tapered insulation.

- Distributors and Retailers: Entities that ensure the consistent availability of certified insulation products support industry-wide adoption and quality assurance.

- Research and Development Institutions: Collaborative research initiatives between industry and academia continue to drive innovations in material formulations and installation techniques.

Legal / Regulatory / Ethical Considerations

Tapered insulation is subject to a range of legal, regulatory, and ethical constraints designed to ensure its safety, performance, and sustainability.

Regulatory Compliance

- Building Regulations: In many jurisdictions, including the United Kingdom, tapered insulation systems must adhere to regulations such as Part L, which governs energy efficiency. These regulations ensure that roofing assemblies contribute to overall energy conservation by reducing heat loss.

- British Standards: Products and installation practices are evaluated against industry standards such as BS6229 (for flat roofs) and BS5534 (for traditional slating and tiling). Compliance with these standards is critical for ensuring product reliability and performance.

- Certification and Testing: Contractors and manufacturers must participate in certification programmes that verify the quality and performance of insulation products. These certifications provide assurance that installations meet requisite safety and efficiency benchmarks.

Ethical and Environmental Considerations

- Sustainable Practices: The production, installation, and long-term performance of tapered insulation are increasingly subject to environmental scrutiny. Manufacturers are encouraged to employ sustainable production methods and materials to minimise environmental impact.

- Heritage Conservation: When applied in heritage buildings or retrofitting projects, tapered insulation must be implemented in a manner that preserves the aesthetic and structural integrity of traditional leadwork. This ensures that modern energy efficiency improvements do not compromise historically significant building elements.

- Transparency and Accountability: Ethical practices require that performance data, installation processes, and compliance with regulatory standards are transparently documented. This supports informed decision-making by building owners and contributes to industry-wide quality assurance.

Performance Metrics / Data / Measurements

The evaluation of tapered insulation is carried out using standardised performance metrics and specialised testing methods that quantify thermal efficiency and water management capabilities.

Thermal Metrics

- U-value: A key performance metric that measures the rate of heat loss through the insulation. Lower U-values indicate better thermal performance.

- R-value: This is the inverse of the U-value and represents the material’s inherent resistance to heat flow. Higher R-values denote superior insulation efficiency.

- Lambda Value: The lambda value quantifies the material’s thermal conductivity, providing insights into its ability to retard heat transfer. This metric is crucial for assessing the performance of tapered insulation in various environmental conditions.

Energy and Environmental Measurements

- Energy Efficiency: Performance data often include energy savings metrics, expressing how much heating or cooling load is reduced by the use of tapered insulation.

- Lifecycle Durability: Testing protocols assess the long-term durability of the insulation, with measurements taken over extended periods under simulated weathering conditions.

- Drainage Testing: Water flow tests are used to validate the efficacy of the tapered gradient in channelling water away from the roof surface, preventing water pooling and leakage.

Testing and Quality Control

- Thermal Imaging: Thermography is routinely employed to identify inconsistencies in insulation application and to detect areas of potential thermal bridging.

- Adhesion and Fastening Evaluations: Mechanical tests measure the strength of the bond between the insulation and the roof deck, ensuring that the system maintains its integrity over time.

- Standardised Protocols: Adherence to testing standards and protocols, as defined by British Standards and building regulations, ensures that performance results are both reliable and comparable across installations.

Challenges / Barriers / Limitations

While tapered insulation offers significant benefits, its implementation is not without challenges. Understanding these limitations is crucial for practitioners and stakeholders to mitigate risks and enhance overall system performance.

Technical and Operational Issues

- Installation Complexity: The requirement for a precise gradient means that installation must be executed with exceptional attention to detail. Deviations from the intended taper can compromise both drainage efficacy and thermal performance.

- Material Variability: Inconsistencies in insulation material properties can lead to variations in performance. For example, differences in adhesive curing times or mechanical fixing strengths may affect the overall durability of the system.

- Integration Challenges: Seamless integration with other roofing components, such as vapour barriers and lead flashings, is critical. Poor integration may lead to water leakage or thermal discontinuities, undermining the benefits of tapered insulation.

Economic Considerations

- Cost Implications: Tapered insulation systems generally command a higher upfront cost compared to conventional flat insulation products. This cost factor can be a barrier for some property owners and developers, particularly in cost-sensitive markets.

- Market Penetration: The relative novelty of tapered insulation in certain regions may lead to hesitancy among contractors and building owners, who may prefer more traditional insulation methods until the benefits are unequivocally demonstrated.

Regulatory and Compliance Challenges

- Evolving Standards: Building regulations and industry standards are continuously updated to reflect new technologies and environmental priorities. Keeping pace with these changes may necessitate adjustments in product formulations and installation practices.

- Certification Complexity: Meeting the rigorous requirements of various certification programmes can be resource-intensive. This is especially true in projects where multiple certifications are required for compliance, such as in heritage or energy-efficient builds.

Impact / Influence / Legacy

The introduction of tapered insulation has had a transformative effect on the roofing industry, influencing design practices, energy efficiency standards, and long-term building performance.

Industry Influence

- Advancements in Roofing Practices: Tapered insulation has paved the way for improved water management in flat roofs, significantly reducing the incidence of leaks and associated maintenance costs. Its integration with lead flashing has also reinforced the performance of traditional roofing assemblies.

- Energy Efficiency Missions: Enhanced thermal performance through tapered insulation contributes directly to reduced energy consumption—a key consideration in both residential and commercial sectors. Over time, this has led to a measurable reduction in heating and cooling demands across installations where the product is used.

- Technological Evolution: The adoption of tapered insulation encourages the ongoing evolution of roofing materials and installation techniques. Its influence has spurred research into new material formulations and the development of more sophisticated installation protocols, driving innovation throughout the industry.

Economic and Environmental Contributions

- Cost Efficiency Over Time: Although the initial investment may be higher, the long-term benefits of reduced maintenance costs and improved energy efficiency can result in overall cost savings. These benefits are particularly significant in large-scale commercial projects and heritage conservation efforts.

- Sustainability Impact: In the context of increasing environmental awareness, tapered insulation contributes to the sustainability of buildings. By lowering energy demands and minimising moisture-related degradation, it plays a role in reducing the overall carbon footprint of construction projects.

Legacy and Ongoing Influence

- Setting New Standards: The evolution of tapered insulation has influenced how buildings are designed and constructed, establishing new benchmarks for both water management and thermal performance. This legacy extends to industry practices, where its principles are increasingly integrated into broader sustainability and efficiency agendas.

- engagement and Research Impact: As a subject of technical research and practical application, tapered insulation has become an integral topic in architectural and engineering training programmes. It encourages a data-driven approach to design and provides a framework for continuous improvement within the industry.

Future Directions, Cultural Relevance, and Design Discourse

Emerging trends in building technology and material innovation continue to shape the future of tapered insulation. As the construction industry evolves, new research, technological breakthroughs, and changing cultural perspectives are poised to further influence the role of tapered insulation in roofing.

Technological Innovations

- Advanced Material Formulations: Future developments may include new polymer composites and hybrid formulations designed to further enhance thermal performance while ensuring superior water drainage. Researchers are investigating materials that not only meet but exceed current regulatory requirements.

- Sensor-Integrated Systems: There is potential for tapered insulation systems to incorporate sensor technologies that monitor real-time thermal performance and moisture levels. Such smart systems could facilitate predictive maintenance and optimise system performance through adaptive control.

- Integration with Renewable Solutions: As buildings increasingly adopt renewable energy technologies, the integration of tapered insulation with solar panels and other energy generation systems may become more prevalent. This could provide comprehensive solutions that address both energy efficiency and sustainable energy production.

Regulatory and Industry Developments

- Updated Building Regulations: Future regulatory revisions may place an even greater emphasis on active water management and thermal efficiency, further solidifying the role of tapered insulation in meeting stringent new standards. This will likely lead to more rigorous testing and certification processes.

- Harmonisation of Standards: Globally, there is a trend toward harmonising building regulations, which may pave the way for tapered insulation systems that comply with international performance criteria. This shift could enhance adoption rates across diverse markets.

- Enhanced Quality Control: Continued advancements in testing methodologies and quality assurance protocols are expected, ensuring that installations consistently meet high standards of performance and safety.

Cultural and Design Considerations

- Heritage Integration: As modern insulation techniques evolve, there is an increasing focus on integrating these technologies into historic and heritage buildings in a manner that respects traditional aesthetics. Tapered insulation offers a viable solution for retrofitting older structures without compromising their historical integrity.

- Architectural Aesthetics: The role of insulation in roof design may also evolve as architects explore creative ways to incorporate functional elements into the overall visual design of buildings. The gradual transitions offered by tapered insulation can be aligned with modern design trends that favour subtle, integrated solutions.

- Sustainable Urban Development: With growing emphasis on sustainable construction practices, tapered insulation is positioned to play a key role in urban development projects that emphasise energy conservation, reduced maintenance costs, and long-term environmental benefits.

Research and Collaborative Dynamics

- Interdisciplinary Collaboration: Future research examining tapered insulation is likely to involve interdisciplinary collaborations among materials scientists, structural engineers, architects, and environmental researchers. This collaborative approach will drive further innovations, ensuring that the technology evolves in step with broader industry needs.

- Quantitative Modelling and Simulation: Advances in computational methods are enhancing the ability to model complex roof assemblies, leading to more accurate predictions of thermal performance and water drainage efficacy. These models will support the optimization of tapered insulation designs for diverse building types and climates.

- Academic and Industry Dialogues: Continued dialogue between academic institutions and industry practitioners will be instrumental in addressing emerging challenges and refining best practices. Such discussions will underpin future updates to standards and regulatory frameworks, ensuring that tapered insulation remains at the forefront of roofing technology.