Warm roof construction offers an integrated approach to roofing that places the insulation above the main structural deck, ensuring that the entire roof assembly remains within the conditioned space. The system combines modern insulation and membrane technologies with traditional waterproofing and leadwork methods, balancing performance with heritage aesthetics. Its application spans residential, commercial, and heritage projects, emphasising sustainability and long-term operational reliability.

Overview / Context

Warm roof construction represents a paradigm shift from the traditional cold roof method by eliminating the ventilated space that often exists in older roofing designs. By installing a continuous layer of insulation on top of the deck, the system maintains a uniform temperature across the roof structure, reducing thermal bridging and improving energy conservation. The design is particularly relevant in contexts where heating efficiency is critical, such as in regions with colder climates or strict energy consumption regulations.

This method also addresses moisture management challenges by incorporating a vapour control layer (VCL), which minimises condensation within the roof assembly. The continuous insulation layer not only enhances thermal performance but also contributes to improved structural stability. In many cases, warm roof construction is combined with traditional lead flashing to secure junctions and intersections, which is especially important in heritage buildings where historical aesthetics must be preserved.

Etymology or Name Origin

The term “warm roof” originates from the arrangement of insulation directly above the structural deck, ensuring that the entire roof structure is maintained at a higher temperature relative to traditional “cold roofs.” In cold roof constructions, insulation is typically placed below the deck, and a ventilated cavity is left between the deck and the external roof covering. The nomenclature “warm roof” underscores the concept of a continuously heated assembly, which significantly reduces internal heat loss and curtails condensation issues.

Historically, the evolving demands for energy-efficient building envelopes in the late 20th century catalysed the transition from cold roof systems to warm roofs. This evolution was accompanied by advancements in insulation materials and waterproofing membranes, enabling a seamless integration with established techniques such as lead flashing. The synthesis of traditional leadwork with modern thermal systems reflects both an adherence to heritage practices and an adaptation to contemporary energy standards.

History

The progression of warm roof construction is deeply intertwined with the broader evolution of building insulation and energy conservation methods. Early roofing systems were primarily constructed with robust materials like slate, clay, and lead to ensure protection against the elements, yet they offered limited thermal performance. As the energy crisis of the 1970s heightened awareness of energy efficiency, architects and engineers began to re-evaluate conventional roofing methods.

Origins and Early Developments

Initially, roofing installations focused on durability with little emphasis on energy conservation. Traditional methods employed materials such as slate and clay tiles combined with lead flashing to form weather-resistant roofs. However, the shortcomings inherent in cold roof designs—where the insulation was placed on the interior side of the deck—became apparent in terms of heat loss and thermal inconsistency.

Industrial Emergence

The subsequent introduction of synthetic insulation materials, including expanded polystyrene and mineral wool, marked the beginning of a new era. Researchers and practitioners experimented with different configurations, leading to the innovative idea of placing insulation above the roof deck. This early emergence of warm roof construction was driven by the need for improved energy performance while maintaining the structural integrity provided by traditional roofing materials.

Technological Advancements

Technological advances in material science have since refined warm roof systems. The development of high-performance insulation materials such as polyisocyanurate (PIR) and advanced membrane solutions, including liquid-applied and thermo-plastic single-ply systems, has enhanced the efficacy of warm roofs. These materials offer improved thermal resistance, durability, and ease of installation. Additionally, innovations in adhesive bonding and mechanical fixing methods have bolstered the overall performance and longevity of the warm roof assembly.

Modern Evolution

Today, warm roof construction is a well-established solution in both new buildings and retrofits. Modern construction practices leverage digital modelling and simulation to optimise the design and installation of warm roofs. Enhanced quality control, driven by non-destructive testing methods such as thermographic surveys and moisture detection, ensures that these systems meet rigorous performance standards. Moreover, the integration of traditional leadwork into modern warm roof assemblies allows for the preservation of historical aesthetics, a feature particularly valuable in heritage projects.

Concept / Description

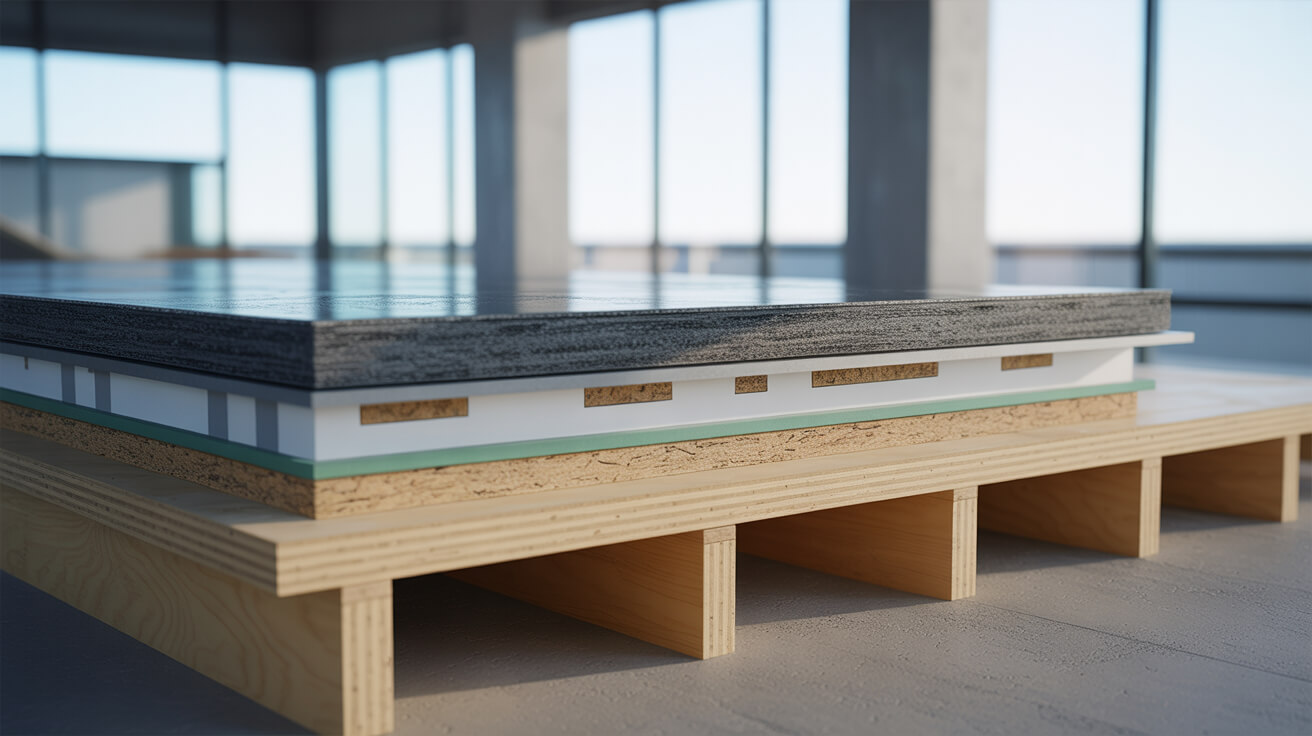

Warm roof construction involves a deliberate assembly of materials designed to create a continuous layer of thermal insulation over the building’s structural deck. The defining characteristic of this system is the placement of the insulation above the deck, ensuring that the entire roof assembly remains within the conditioned envelope of the building. This design minimises thermal bridging and optimises energy retention, and it is configured through several interdependent layers.

Insulation Layer

The insulation layer is pivotal in preventing heat loss. Materials such as polyisocyanurate (PIR), mineral wool, or polyisocyanurate panels are selected for their high R‑values, low thermal conductivity, and resistance to moisture ingress. Uniform insulation across the roof is crucial to reduce cold spots that may lead to condensation or structural damage.

Vapour Control Layer

Positioned immediately below the insulation, the vapour control layer (VCL) acts as a barrier against moisture penetration. This layer must be meticulously sealed using techniques such as lap sealing to ensure that excess moisture is controlled. By maintaining optimal air and moisture balance, the VCL plays an essential role in protecting the insulation and other roofing components.

Roof Deck

The deck provides the primary structural support for the roofing system. Common materials include timber, concrete, and metal, chosen based on the building’s design requirements and load-bearing capacity. The integrity of the deck is critical, as it must withstand not only environmental loads but also the additional weight and thermal stresses introduced by the insulation and membrane layers.

Membrane System

The membrane system serves as the exterior waterproofing barrier that protects the roof from weather elements. Options include bitumen‑based membranes, liquid‑applied coatings, and thermo‑plastic single‑ply membranes (such as PVC or TPO). The choice of membrane depends on factors such as environmental exposure, required durability, and the method of installation. Proper adhesion between the membrane and the underlying layers is essential for long-term performance.

Leadwork Integration

In warm roof systems that incorporate traditional leadwork, lead flashing is used to ensure continuous waterproofing at critical junctions, such as where the roof meets vertical surfaces, around chimneys, or along roof penetrations. Traditional techniques, such as step flashing and apron flashing, are adapted to the warm roof context, thereby combining modern performance with historical authenticity. This integration not only reinforces the waterproofing capability but also supports aesthetic continuity in heritage restoration projects.

Functionality / Purpose / Applications

The primary purpose of warm roof construction is to create an energy-efficient, moisture-controlled roofing system that enhances the thermal performance of a building while ensuring long-term durability. This method is employed to improve indoor comfort and reduce energy consumption by minimising heat loss through a continuous insulation layer. Its practical applications are broad, extending across various types of construction and architectural styles.

Energy Efficiency

- Continuous Insulation: By placing insulation above the structural deck, a warm roof system minimises thermal bridging and maintains a consistent temperature profile, which helps in reducing heating and cooling demands.

- Improved U‑Value: The effectiveness of the insulation layer is measured by its U‑value; a lower U‑value indicates reduced heat transfer, leading to better energy performance.

- Reduced Thermal Gains/Losses: The homogeneous nature of the warm roof minimises the risk of differential thermal expansion, which can lead to energy losses due to uneven heating.

Moisture and Condensation Control

- Effective Vapour Barrier: The vapour control layer prevents warm, moist air from infiltrating the roof assembly, thereby reducing the occurrence of condensation.

- Prevention of Structural Damage: By controlling moisture levels, warm roofs help in mitigating issues such as mould growth, timber decay, and insulation degradation.

- Enhanced Longevity: Keeping the roof assembly free from excessive moisture contributes to longer service life and reduced maintenance requirements.

Structural and Practical Applications

- Retrofitting and New Installations: Warm roof systems are applicable both to new building projects and retrofits where pre-existing roof structures require an upgrade to meet modern energy performance standards.

- Heritage Buildings: In conservation projects, warm roof techniques enable you to combine modern insulation benefits with traditional leadwork methods, ensuring compliance with contemporary energy regulations while preserving historical value.

- Commercial and Institutional Buildings: The system’s ability to provide consistent thermal performance makes it ideal for use in commercial, office, and public buildings where energy demands and occupant comfort are critical considerations.

Environmental and Economic Benefits

- Cost Savings: Over the lifecycle of the building, the energy savings achieved through improved thermal performance can offset the higher initial installation cost.

- Sustainability: Reduced energy consumption contributes directly to lower carbon emissions and aligns with sustainable building certifications.

Classifications / Types / Variants

Warm roof construction encompasses various classifications based on the choice of materials, system configurations, and integration techniques with leadwork. These classifications are often determined by the performance requirements and the specific application of the roof system.

Insulation Material Variants

- Polyisocyanurate (PIR): Offers high thermal resistance and is prized for its efficiency in reducing heat loss while being relatively resistant to moisture.

- Mineral Wool: Provides robust fire resistance and acoustic insulation, making it a popular choice in situations where noise reduction is as important as thermal performance.

- Polyisocyanurate Panels: Pre-formed panels that ensure uniformity in insulation quality and performance, suitable for a range of building types.

Membrane System Variants

- Bitumen-Based Membranes: Traditional systems known for their robustness and long-term waterproofing properties; however, they require careful application to avoid irregularities.

- Liquid-Applied Membranes: These membranes offer a seamless application that is particularly advantageous in roofs with complex geometries or intricate detailing.

- Thermoplastic Single-Ply Membranes (PVC/TPO): Known for their flexibility and ease of installation, these membranes deliver high durability and are resistant to wind uplift and UV degradation.

Leadwork Integration Variants

- Traditional Lead Flashing: Maintains historical authenticity in heritage constructions through techniques such as step flashing and apron flashing.

- Modern Lead Alternatives: Where environmental or structural concerns limit the use of traditional lead, polymer-based or composite alternatives are used, designed to mimic the performance characteristics of conventional leadwork.

Assembly Configuration Variants

- Continuous Insulation Systems: Designs where the insulation extends fully over the roof deck, thereby eliminating thermal bridges entirely.

- Hybrid Systems: Combinations of warm and cold roof techniques tailored for specific structural requirements or to meet regulatory constraints in retrofitting projects.

Systems / Tools / Methodologies

The implementation of warm roof construction involves a suite of specialised tools and methodologies that ensure effective installation and sustained performance. The systematic approach to building these systems is crucial for achieving optimal functionality.

Installation Tools

- Adhesive Bonding Systems: Advanced adhesives are used to secure the insulation and membrane layers, ensuring continuity and resistance to thermal movement.

- Mechanical Fixings: The use of nails, screws, and clips is essential in anchoring the layers, with techniques selected to minimise disturbance to the insulation’s effectiveness.

- Digital Measurement Instruments: Tools such as thermal cameras and moisture metres are employed to verify that the system is installed correctly and performing as intended.

Methodologies

- Layer-by-Layer Assembly: Installation is performed sequentially, with each layer (insulation, vapour control, deck, membrane, and leadwork) installed in a controlled manner to ensure maximum integration and performance.

- Pre-Installation Simulation: Digital modelling techniques simulate the roof’s thermal performance and identify potential weaknesses before physical installation begins.

- Post-Installation Testing: Standard procedures, including U‑value and moisture content assessments, confirm that the assembled system meets industry benchmarks for thermal efficiency and waterproofing.

Quality Assurance Protocols

- Standard Operating Procedures (SOPs): Detailed installation guidelines ensure that every phase—from material selection to final inspection—is executed to strict quality standards.

- Regulatory Compliance Reviews: Frequent inspections and audits verify that the installation adheres to the applicable building regulations and British Standards.

- Lifecycle Monitoring: Ongoing performance assessments throughout the roof’s service life allow for timely interventions and adaptations as needed.

Stakeholders / Entities Involved

Multiple stakeholders contribute to the successful design, installation, and maintenance of warm roof construction, each playing a distinct role in ensuring that the system performs optimally throughout its lifecycle.

Industry Participants

- Roofing Contractors: These professionals execute the practical aspects of installing warm roof systems, employing the necessary skills to integrate diverse materials into a cohesive assembly.

- Material Suppliers: Providers of advanced insulation, membrane products, and traditional lead materials deliver the essential components that determine the overall performance of the roofing system.

- Certification Bodies: Independent agencies that conduct performance tests and compliance audits to verify adherence to industry standards.

- Regulatory Authorities: Government entities and standard-setting organisations, such as the British Standards Institution, establish the frameworks and guidelines that inform warm roof construction design and implementation.

Professional and Technical Support

- Architects and Engineers: Operating at the conceptual and design phase, they ensure that warm roof systems are seamlessly integrated into overall building designs, balancing aesthetic considerations with performance requirements.

- Heritage Consultants: When warm roof systems are applied to historical buildings, these experts advise on methods that preserve original architectural features while incorporating modern energy efficiency measures.

End Users

- Property Owners and Managers: They benefit from enhanced energy savings and reduced maintenance costs offered by warm roof systems. Their input is critical in decision-making processes related to system selection and upkeep.

- Facilities Directors: Responsible for ongoing building performance, these professionals rely on the durability and reliability of warm roof systems to ensure that the building envelope performs consistently under varying operational conditions.

Legal / Regulatory / Ethical Considerations

Warm roof construction is governed by a complex set of legal, regulatory, and ethical standards designed to ensure both performance and safety. These guidelines influence every stage of design, installation, and maintenance.

Regulatory Frameworks

- Building Regulations: In the United Kingdom, warm roof systems must conform to standards set out in Part L, which addresses energy efficiency, as well as Part F, which governs ventilation requirements to avoid condensation.

- British Standards: Compliance with standards such as BS5534 (focused on roofing work) and BS8612 (dry fix systems) is critical, ensuring that installation practices meet rigorous technical benchmarks.

- Heritage Conservation Guidelines: For projects involving historical buildings, additional guidelines from conservation bodies and statutory agencies, such as Historic England, dictate how warm roof systems are implemented without compromising heritage values.

Ethical and Environmental Standards

- Sustainability: Ethical construction practices demand that materials used in warm roof systems exhibit low embodied energy and high recyclability. This contributes to the overall sustainability of the building project.

- Health and Safety: Installation processes must adhere to strict safety protocols to protect workers and occupants. Detailed risk assessments and the use of proper personal protective equipment (PPE) are essential components of ethical execution.

- Transparency in Performance: Contractors and suppliers are ethically bound to provide accurate information regarding system performance, warranties, and maintenance practices, ensuring that end users understand the capabilities and limitations of their roofs.

Performance Metrics / Data / Measurements

Evaluating the performance of warm roof construction systems is essential to ensure that they meet both energy efficiency and structural durability standards. A range of metrics is used to assess these characteristics.

Thermal Performance and Energy Efficiency

- U‑Value and R‑Value Assessments: These metrics evaluate the insulation’s effectiveness in reducing heat transfer. A low U‑value denotes superior insulation, whereas a high R‑value indicates high thermal resistance, thereby lowering energy demand.

- Thermal Bridging Analysis: Infrared thermography and other digital tools are deployed to detect areas where insulation might be compromised, ensuring that thermal bridging is minimised across the roof surface.

Moisture and Condensation Control

- Vapour Transmission Rates: Standardised tests measure the effectiveness of the vapour control layer in preventing moisture from penetrating the insulation. The balance between permeability and moisture resistance is crucial.

- Condensation Monitoring: Sensors and periodic inspections help track the formation of condensation within the roof assembly, ensuring that any issues are addressed swiftly to avoid material degradation.

Structural and Durability Evaluations

- Load Testing: The roof’s ability to bear physical loads, including snow and wind, is assessed to confirm that the structural deck and its fixings are adequate.

- Membrane Durability: Laboratory and field assessments measuring UV resistance, temperature fluctuation effects, and chemical stability provide insights into the membrane’s expected service life.

- Lifecycle Performance Analysis: Economic evaluations compare the initial costs against long-term savings in energy and maintenance, offering a comprehensive view of the roof’s overall value.

Quality Assurance and Benchmarking

- Certification Audits: Regular inspections verify that installations align with industry standards such as BS5534 and prevent issues related to improper installation.

- Performance Data Collection: Detailed data on thermal performance, moisture management, and structural integrity is collected throughout the system’s use, allowing for continuous improvement and benchmarking against industry standards.

Challenges / Barriers / Limitations

Despite its advantages, warm roof construction faces several operational and systemic challenges that must be addressed to ensure optimal performance and longevity.

Technical Challenges

- Complex Installation Requirements: The installation of a continuous insulation layer over the structural deck demands precise sequencing and skilled workmanship. Errors in adhesive application or incorrect layer alignment can result in significant performance issues.

- Material Compatibility Issues: Integrating various materials—each with different expansion rates and chemical properties—requires careful coordination. Incompatible materials can lead to delamination or premature failure of the roof assembly.

- Thermal Bridging Vulnerabilities: Even minor gaps in insulation installation can create thermal bridges, leading to localised heat loss and potential condensation issues that compromise the entire system.

Economic and Logistical Barriers

- Higher Initial Investment: Warm roof systems generally require a higher upfront cost due to the premium insulation materials and specialised installation techniques. This economic barrier may be a deterrent in projects with constrained budgets.

- Long-Term Maintenance Complexity: While designed for durability, any deficiencies in the system may be challenging to repair, especially in retrofitting scenarios where existing structures must be modified to accommodate the new system.

- Supply Chain Variability: Consistency in quality and availability of advanced materials can vary, affecting project reliability and overall system performance.

Regulatory and Compliance Constraints

- Multiplicity of Standards: Warm roof construction must comply with an array of regulations and standards, from local building codes to specific British Standards. Navigating these requirements, particularly in retrofit projects, can introduce significant complexity.

- Heritage Building Restrictions: For heritage properties, there are additional constraints that require balancing modern energy performance with the preservation of historical architectural features. This often necessitates specialised expertise and tailored solutions.

Environmental Considerations

- Moisture Management in Extreme Climates: In regions with high humidity or significant temperature fluctuations, controlling moisture within the roof assembly remains a critical challenge. Advanced monitoring and regular maintenance are essential to sustain performance.

- Adaptability to Diverse Structures: Warm roof systems must be customised for various roof geometries and material compositions, which can introduce additional layers of complexity and risk during installation.

Impact / Influence / Legacy

The introduction and advancement of warm roof construction have significantly influenced the roofing industry, altering standards, enhancing building performance, and shaping sustainable construction practices.

Energy Efficiency and Sustainability

- Reduction in Energy Consumption: By providing a continuous layer of insulation, warm roof systems reduce heat loss and improve energy efficiency, leading to lower operational costs and reduced carbon emissions.

- Sustainability Contributions: The systems utilise advanced insulation and membrane technologies that lower the overall environmental impact of buildings, supporting green building certifications and sustainable design practices.

Technological Advancements in the Roofing Sector

- Innovative Materials Development: The demand for high-performance insulation and waterproofing membranes has driven material innovations, resulting in products with enhanced thermal performance and extended service life.

- Integration of Traditional and Modern Techniques: Warm roof construction epitomises the successful integration of modern engineering with traditional methods, particularly through the incorporation of leadwork—a practice that preserves historical heritage while delivering improved energy efficiency.

Economic and Industrial Influence

- Long-Term Asset Value: Buildings equipped with warm roof systems typically experience reduced energy bills and lower maintenance costs, providing long-term economic benefits that enhance asset value.

- Standards Evolution: The success of warm roof systems has informed revisions in building codes and industry standards, establishing new benchmarks for energy efficiency and construction practices.

Cultural Impact and Architectural Legacy

- Preservation of Heritage Aesthetics: In projects involving historical structures, warm roof construction allows for the preservation of traditional leadwork and architectural features while meeting modern performance standards.

- Legacy of Durability and Performance: The long-term durability and superior performance of warm roof systems have established them as a robust alternative to traditional roofing methods, influencing both contemporary design and restoration practices.

Future directions, cultural relevance, and design discourse

Emerging trends and technological innovations promise to further refine warm roof construction, ensuring that it remains at the forefront of sustainable building practices and architectural design.

Technological Innovations

- Enhanced Digital Modelling: Future advancements in computer-aided design and thermal simulation promise to yield even more precise customization of warm roof systems. These tools can predict and optimise performance in real time, allowing for individualised solutions based on specific building characteristics.

- Next-Generation Materials: Research into novel insulation materials, including nanotechnology-enhanced products and bio-based alternatives, is expected to produce even lower thermal conductivities and improved environmental profiles. Such innovations aim to further reduce energy consumption while meeting stringent regulatory requirements.

- Smart Sensors and Monitoring: The integration of IoT devices and smart sensors with warm roof systems can facilitate continuous performance monitoring. Data on thermal performance, moisture levels, and structural health can be used to predict maintenance needs and optimise service intervals, ensuring that the system remains effective over its full lifespan.

Cultural Relevance and Architectural Integration

- Bridging Tradition and Modernity: As architectural trends increasingly favour sustainable design, warm roof construction stands out as a method that harmonises contemporary energy efficiency with traditional building techniques. This fusion supports both new construction and the restoration of heritage buildings, ensuring that historical aesthetics are preserved while embracing modern advancements.

- Evolving Aesthetic Considerations: Future designs may see warmer roof assemblies subtly integrated into the overall visual language of a structure. Innovations in material finishes and installation techniques may allow architects to expose or artistically conceal the functional layers, creating novel aesthetic effects without compromising performance.

- Role in Sustainable Urban Development: With an increasing emphasis on reducing urban carbon footprints, warm roof systems are set to become a key component of sustainable city planning. Their ability to significantly reduce heating and cooling demands aligns with broader trends toward energy-conscious construction and green building practices.

Design Discourse and Critical Perspectives

- Retrofitting and Adaptive Reuse: Ongoing debates in industry circles focus on the feasibility and benefits of retrofitting existing buildings with warm roof technology. These discussions emphasise the trade-offs between maintaining historical construction methods and achieving substantial improvements in energy efficiency.

- Ethical and Environmental Stewardship: As concerns about climate change intensify, there is growing emphasis on ethical construction practices that prioritise sustainability, resource efficiency, and low environmental impact. Future discourse will likely stress the importance of transparent lifecycle assessments and responsible material sourcing in warm roof assemblies.

- Integration of Emergent Technologies: The application of artificial intelligence and machine learning to roofing design and maintenance is an emerging field. These technologies can enhance predictive analytics, optimise material performance, and enable responsive adjustments to environmental changes, thus shaping the future evolution of warm roof construction.

- Industry Standards and Policy Evolution: As warm roof technology continues to advance, regulatory frameworks will evolve. Future guidelines and standards may incorporate specific performance criteria for warm roof constructions, prompting manufacturers and contractors to adopt best practices that ensure both safety and superior performance.